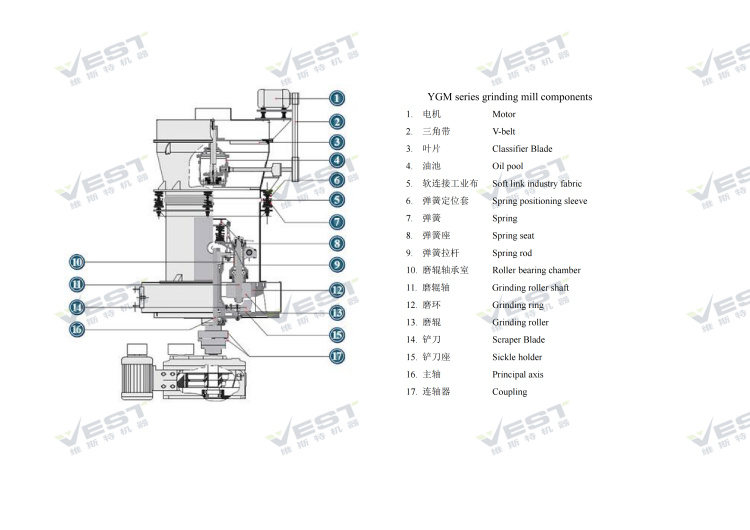

YGM Raymond Grinding Mill Working principle

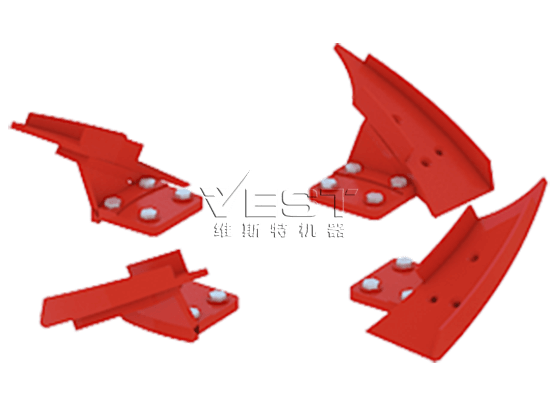

In the high-pressure medium-speed YGM Raymond Grinding Mill, a high-pressure spring with a pressure of 1000-1500 kg is fastened on the roller hanger. After YGM Raymond Grinding Mill starting to work, the roller rotates around the main shaft and rolls close to the grinding ring under the action of the high-pressure spring and centrifugal force. Its rolling pressure is 1.2 times higher than that of the Raymond mill under the same power conditions, so the output is greatly improved. When the material to be ground enters the grinding chamber, it is scooped up by the scraper and sent to the grinding roller and the grinding ring for rolling.

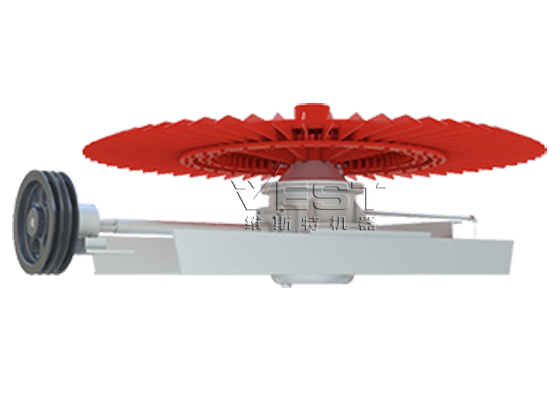

The rolled powder is brought into the analyzer with the circulating air of the blower. The qualified fine powder flows into the cyclone powder collector with the air and becomes the finished product. The large particles fall back to the re-grinding. The circulating air returns to the blower and repeats the above process. The remaining air enters the pulse dust collector for purification. When the roller and the grinding ring reach a certain wear, the length of the high-pressure spring is adjusted to maintain a constant rolling pressure between the roller and the grinding ring, thereby ensuring stable output and fineness.

Why choose YGM Raymond Grinding Mill?

The Raymond mill is actually the earliest powder grinding mill equipment, and YGM series high-pressure mill is improved updated on the basis of the Raymond mill. The difference lies in the feed particle size, discharge particle size, and capacity.

1.Feed size. For original R-series Raymond mill, the smaller feed, it will be more stable output and higher processing efficiency. While the feed size of YGM Raymond Grinding Mill is larger than the range of Raymond mill.

2.Output particle size: the discharging particle size of Raymond mill is in the range of 30 mesh to 325 mesh, while the output particle size of YGM Raymond Grinding Mill is in the range of 80 mesh to 425 mesh. The finished product is finer and the screening rate is higher.

3.Capacity: Due to the strong pressure of the high-pressure spring, the output of the high-pressure grinding mill will be higher than that of Raymond mill.

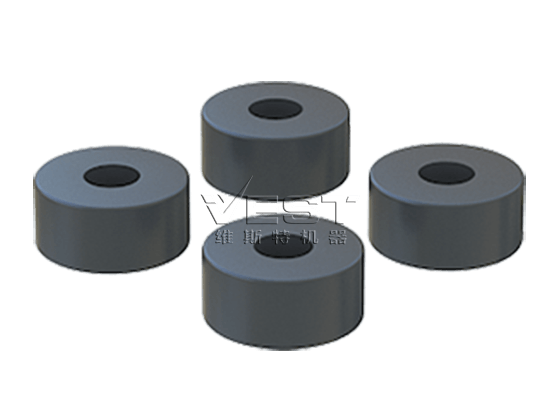

4. In the process of long-term use, when the loss of the grinding roller and grinding ring is serious, even if the bolt and other parts are adjusted, it can not be tightly ground, and the finished powder can not reach the required finness. At this time, only the fragile ones can be replaced. Parts, but the high-pressure mill will not be like this. Under normal circumstances, before reaching the grinding critical point, the high-pressure device can be adjusted to make the grinding roller and the grinding ring tightly pressed to maximize the use.

Maximino

From Saudi Arabia

"VEST mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider VEST is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"VEST has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a VEST grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to VEST mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves VEST’s ‘Built for Decades’ promise."