In today’s fast-paced construction, mining and recycling industries, mobile crushing has become a powerful alternative to traditional fixed or stationary rock crushing equipment. Mobile crushing plants, with the ability to move between crushing sites, are revolutionizing the way rock and mineral materials are processed.

What is mobile crushing?

Mobile crushing equipment is a type of rock crushing equipment mounted on wheels or tracks, allowing it to move freely around the job site. It is used to break large rocks, stones, and ores into smaller particles.

VEST Machinery’s mobile crushing plants integrate feeding, crushing, screening, and conveying, and are widely used in crushing, shaping, and sand processing for mining, aggregate, and waste processing.

Advantages of a Mobile Crushing Plant

A mobile crushing plant, as a group of large crushing plants, is equivalent to a crushing production line. Choosing a mobile crushing plant over a stationary rock crusher offers several significant benefits:

1. Portability and Flexibility

Mobile rock crushers are easy to set up, dismantle, and transport. This mobility is particularly important when materials need to be processed in multiple or remote locations. This flexibility is beneficial for job sites with constantly changing requirements.

2. Modular Design

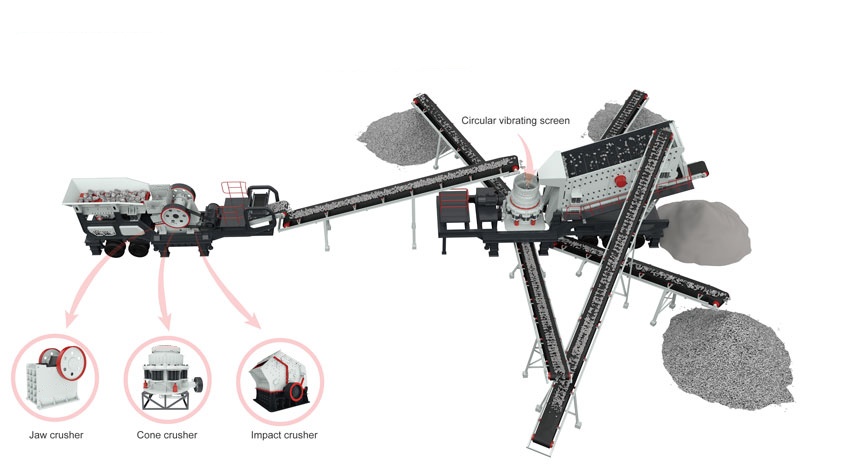

Modern mobile crushers utilize a modular system. A single chassis can accommodate different types of crushers, such as jaw crushers, cone crushers, and impact crushers. This makes it easy to upgrade or change the processing configuration based on project needs.

3. Cost-Effectiveness

Mobile crushers typically require less infrastructure and installation time. By processing materials at the source, they eliminate the need to transport raw materials to a central crushing facility, helping to reduce transportation and labor costs.

4. Reduced Environmental Impact

Mobile crushing plants crush materials on-site, minimizing dust emissions and trucking, making them a more sustainable option. Its energy-saving engine and dust suppression system further enhance its environmental friendliness.

When to Use Mobile Crushing Equipment?

Don’t hesitate to use mobile crushing equipment when you have the following situations:

- Temporary crushing projects

- Short-term construction and mining operations

- Multiple construction sites using similar materials at different times

- Urban areas with strict space and environmental regulations

- Projects in remote areas where transporting raw materials is costly or impractical

If your project involves seasonal or mobile work or is under tight timelines, investing in a mobile crushing plant may be the best option.

Applications of Mobile Crushing Equipment

Mobile rock crushers can be used to crush hard and medium-hard rock, stone, minerals, construction waste, concrete, and other aggregates:

Natural stone: granite, basalt, marble, sandstone, limestone, bluestone, diabase, andesite, sandstone, etc.

Minerals: dolomite, iron ore, copper ore, coal, quartz, cobblestone, molybdenum ore, limestone, coal, etc.

Waste: slag, gangue, tailings, etc. Recycling materials: Concrete, construction waste, bricks, glass, ceramics

These industries require large numbers of mobile crushing plants:

Mining: Crushing and processing ore

Construction: Producing concrete and asphalt aggregates

Recycling: Recycling demolition and construction waste (C&D waste)

Quarrying: Crushing rock into crushed stone, gravel, or stone chips

Infrastructure: Crushing materials for infrastructure projects such as highways, railways, and roads.

Types of Mobile Crushing Equipment

Mobile crushing equipment comes in various types. Based on their travel method, they are categorized as mobile crushers and portable crushers.

1. Mobile Crusher

Mobile crushers, also known as crawler crushers, are self-propelled by hydraulically driven tracks, making them capable of navigating diverse terrains, slopes, and remote locations. They are commonly used on mining and rugged construction sites.

A mobile crushing station is a crushing production line that can be equipped with a mobile rock crusher and screen according to the crushing requirements.

Crusher Types: Mobile Jaw Crusher, Mobile Cone Crusher, Mobile Impact Crusher, Mobile Crusher (Sand Making Machine)

- Feed Size: 185–700 mm

- Capacity: 60–500 tons per hour

- Weight: 32–60 tons

- Powertrain: Full hydraulic, D-type hybrid, E-type external power supply, and more. Customers can choose based on fuel costs, operating expenses, and other factors.

- Advanced hydraulic powertrain and dust and noise reduction technologies are used for environmental protection and energy conservation. Installation is quick, taking only 4 to 6 hours.

- Easy to operate and maintain—requiring only one or two workers, the machine can be quickly moved and crushed with a single button start or stop.

2. Portable Crusher

Portable crushers, also known as wheel crushers or tire crushers, are semi-mobile and typically towed by a truck. This type of rock crusher is ideal for urban construction, road construction, and building demolition.

Specifications:

- Crusher Types: Mobile Jaw Crusher, Mobile Cone Crusher, Mobile Impact Crusher, Mobile Hammer Crusher

- Feed Size: 300–800 mm

- Capacity: 50–300 tons/hour

- Weight: 31–65 tons

- Power: Powered by mains electricity or a diesel generator, it operates smoothly even during power outages or in rural areas without electricity.

- Equipped with an onboard belt drive and independent control system, it can be quickly installed on site without disassembly during transportation.

- No foundation required—the outrigger track shoe assembly can be quickly installed on site and folds for easy transportation, reducing foundation investment. The entire installation process takes only 2 to 3 days.

- Operation and maintenance are easy, with ladders and wide steps for convenient inspection and maintenance.

How does a mobile crushing station work?

The typical operating principle of a mobile crushing station is as follows:

1. Feeding: Large materials are fed into a vibrating feeder.

2. Primary crushing: A mobile jaw crusher breaks down the large materials.

3. Secondary crushing: The crushed materials are fed into an impact crusher or cone crusher for secondary and tertiary crushing.

4. Screening: A vibrating screen sorts the materials by size, sending qualified materials to a conveyor and returning unqualified materials for further crushing, forming a closed-loop system.

5. Output: Qualified finished aggregates are discharged via a belt conveyor.

Mobile crushing stations combine feeding, crushing, screening, and conveying into a single crushing workflow, minimizing downtime and maximizing productivity through a continuous crushing process.