Limestone is a common mineral widely used in construction, chemical processing, and other industries. Limestone grinding equipment is an essential tool in limestone processing.

This article provides a detailed introduction to limestone grinding equipment, helping you better understand the various equipment and their functions, enabling efficient and environmentally friendly production.

Uses of limestone powder

| Fineness (Mesh) | D95/D99/D99.9/D99.95 | Main Applications | Applications |

| 200 | D95 200 mesh | Anhydrous calcium chloride, glass, cement, building materials, livestock feed | Chemical industry, construction, feed |

| 325 | D99 325 mesh | Plastics, gypsum, plywood, paint, building materials | Construction, chemical industry, coatings |

| 325 | D99.9 325 mesh | Wire insulation, rubber moldings, asphalt felt | Electronics, construction, industry |

| 400 | D99.95 400 mesh | High-fineness industrial applications such as coatings, plastics, papermaking | High-tech, industry |

| 40-150 | 40-150 mesh | Architectural coatings, chemical raw materials, papermaking, sealants | Construction, chemical industry, industry |

| 150-200 | 150-200 mesh | Highway asphalt, desulfurization agent | Transportation, environmental protection |

| 250-325 | 250-325 mesh | Power plant desulfurization, high calcium content | Energy, environmental protection |

| Within 200 | Within 200 mesh | Feed additives, cosmetics, plastics, rubber | Agriculture, cosmetics, industry |

Explanation:

- Fineness : Expressed in mesh size. The higher the mesh size, the finer the particles.

- D95/D99: Indicates the mesh size at which 95% or 99% of the particles pass through. This is used to describe the particle size distribution of a powder.

3 types of limestone grinding machines

In the limestone grinding process, three common grinding equipment types are Raymond mills, HGM ultrafine mills, and vertical mills. Each has distinct characteristics and advantages, suitable for different grinding particle sizes and applications. Below is a detailed comparison:

1. Raymond Mill

Features:

The Raymond mill is a traditional grinding equipment with a simple structure and easy operation. It is suitable for materials of various hardnesses, such as limestone and calcite.

It works by grinding the material into a fine powder through the squeezing action of the grinding rollers and grinding rings.

It has a high screening rate of up to 99%, and can produce limestone powders with mesh sizes of 80-400.

Advantages:

Suitable for small and medium-scale production, with low costs and easy maintenance.

Suitable for processing medium-hardness materials, such as limestone.

Limitations:

Relatively low energy efficiency and limited processing capacity for ultrafine powders.

The product fineness adjustment range is limited, typically between 80-400 mesh.

2. HGM Ultrafine Mill

Features:

The HGM Ultrafine Mill is a new type of ultrafine grinding equipment capable of producing finer powders, with particle sizes reaching 80-800 mesh.

It offers higher grinding efficiency and finer particle size control.

Advantages:

Suitable for industrial applications requiring high fineness, such as coatings, plastics, and papermaking.

Products offer uniform particle size, suitable for fine processing.

Limitations:

High initial investment, complex equipment structure, and high maintenance requirements.

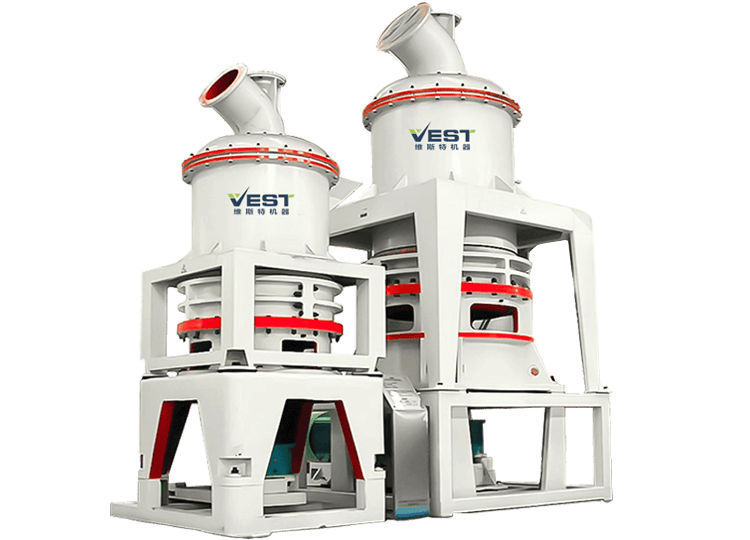

3. Vertical Mill

Features:

The vertical mill is a highly efficient grinding equipment that integrates crushing, drying, grinding, and grading, suitable for grinding a variety of materials.

Its vertical structure occupies a small footprint, is compact, and is suitable for large-scale production.

Advantages:

High grinding efficiency and low energy consumption make it suitable for large-scale production.

Products offer a wide and adjustable particle size range, suitable for a variety of materials.

Limitations:

High initial investment, complex equipment structure, and high maintenance requirements.

Summary

Raymond mill: Suitable for small- to medium-scale production, low-cost, and suitable for grinding medium-hard materials.

HGM ultrafine mill: Suitable for industrial applications requiring high fineness, producing a finer product.

Vertical mill: Suitable for large-scale production, high efficiency, and suitable for large-scale industrial applications.

Contact us to select the right limestone grinding equipment for your specific needs!

Tips for choosing a limestone grinding machine

Each limestone grinder has its own application scopes. Customers can choose according to the feed size, required fineness of limestone powder, output and so on.

| Equipment | Vertical Mill | Raymond Mill | HGM Ultrafine Grinding Mill |

| Grinding Degree | Coarse Powder | Coarse Powder | Fine Powder |

| Capacity | 8-176 tons/day | 8-176 tons/day | 30-800 kg/hour |

| Feed Size | ≤30 mm | ≤30 mm | ≤20 mm |

| Discharge Size | 80-325 mesh | 80-325 mesh | 80-1250 mesh |

Conclusion

Limestone grinding is a key process in limestone powder production. The process flow and equipment selection must be optimized based on specific application requirements to ensure product quality and production efficiency. Contact us today to customize your limestone grinding plant.