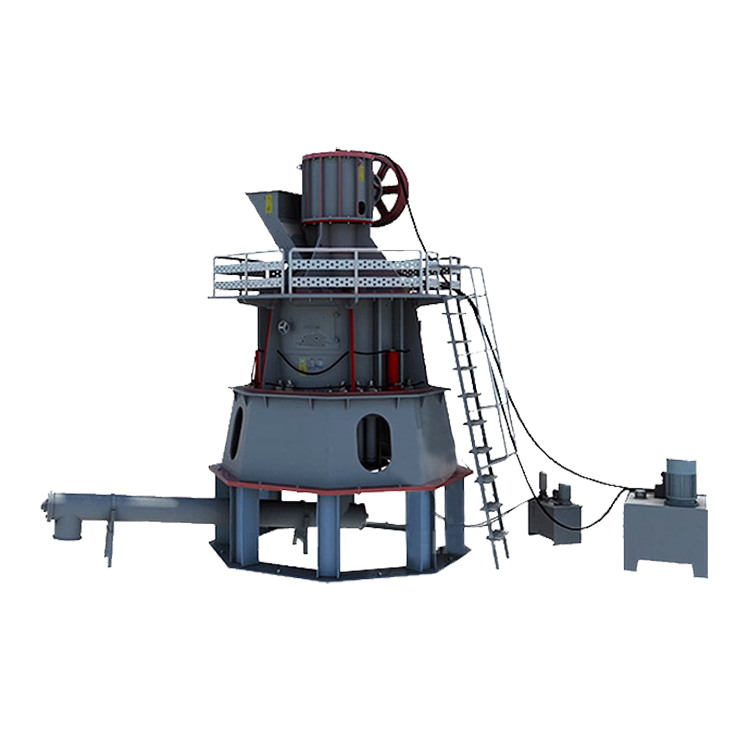

Straight-Through Centrifugal Mill

The Straight-through Centrifugal Mill is suitable for industries such as metallurgy, building materials, chemicals, and mining. It supports both dry and wet production modes and can process high-hardness materials such as silicon carbide and corundum with a Mohs hardness of ≤9.

Are you interested in our machines? Custom Solution for your needs.Contact Us.

Straight-Through Centrifugal Mill Details

- DATE

- APPLICATION FIELD

- Reviews (3)

*The capacity and output will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

| Model | Capacity (t/h) | Max feeding size(mm) | Finished powder size(mm) |

| M-900 | 15-20 | 30 | -1.5 |

| M-1050 | 25-30 | 35 | -1.5 |

| M-1150 | 45-50 | 45 | -1.5 |

Leave a review

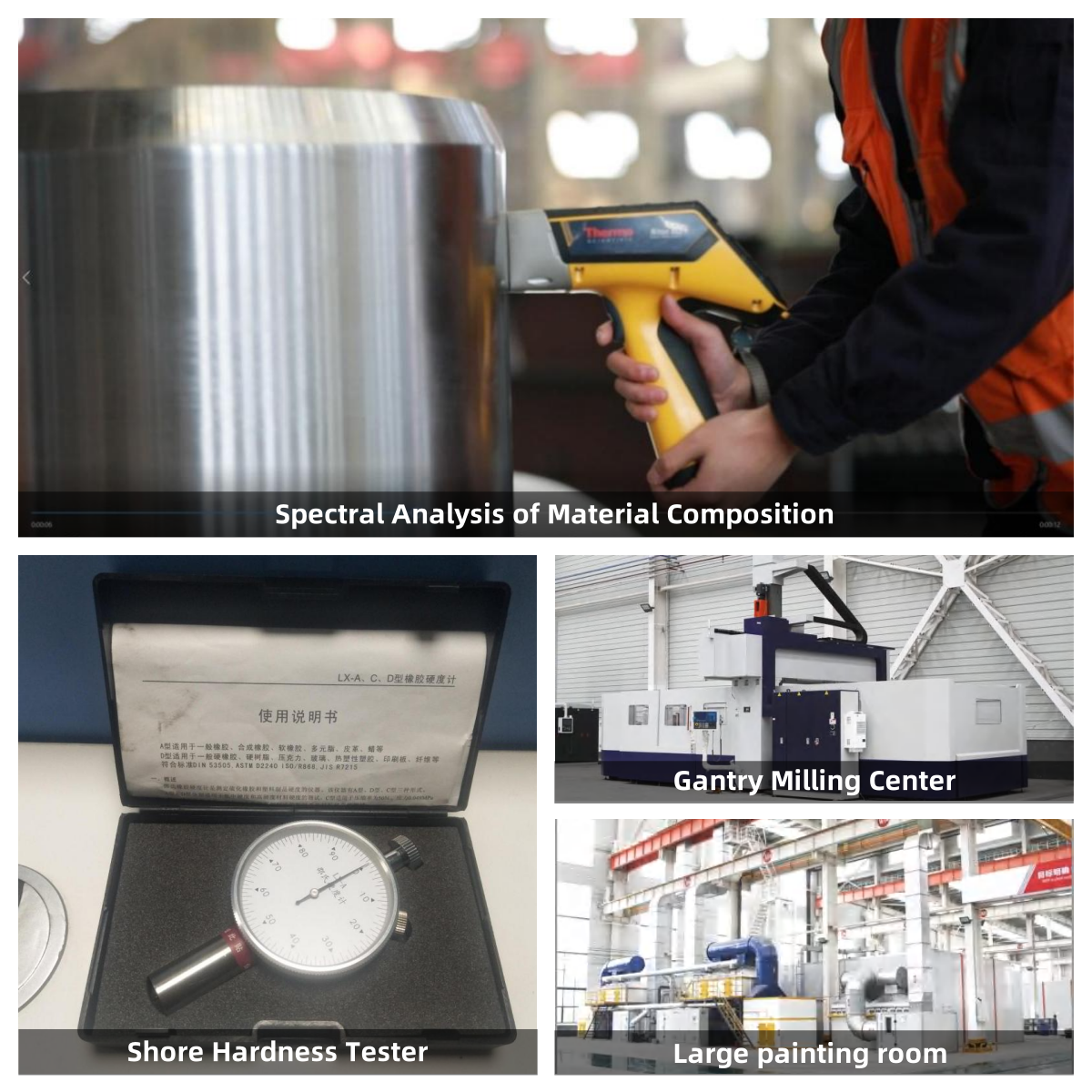

Why Choose VEST Straight-Through Centrifugal Mill

-

High cost performancelowest price, best work return

-

High quality spare partsMn13Cr2/Mn18Cr2,long lifetime, full service system, saving costs

-

High Crushing efficiencyThe design of deep V crushing chamber adjustable final size, reliable performance, easy maintenance

-

Energy savingSingle machine saves 15% to 30% energy,. Low noise and less dust.

Maximino

From Saudi Arabia

"VEST mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider VEST is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"VEST has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a VEST grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to VEST mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves VEST’s ‘Built for Decades’ promise."