SOLUTION

Slag Grinding Production Line

Processing Overview

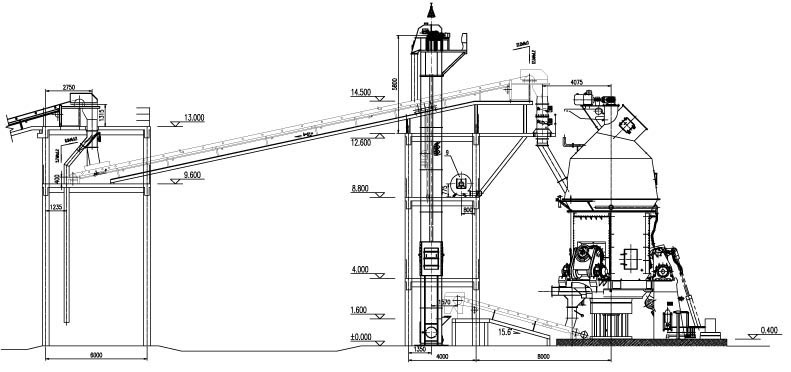

Process flow diagram

Introduction of Slag Grinding Production Line

Slag is a by-product of the metallurgical industry. Traditional storage methods not only occupy land but also pollute the environment. This production line transforms industrial waste into high-value-added slag powder (specific surface area ≥420 m²/kg) through grinding, drying, grading, and collection processes.

It has a wide range of applications, including:

• Cement production: as an admixture to improve cement properties and durability.

• Road construction: used in road base and pavement materials.

• Environmentally friendly building materials: used in environmentally friendly building materials and insulation materials.

Detailed Process Flow of a Slag Grinding Line

1. Raw Material Pretreatment

• Drying: The moisture content of the slag must be controlled to ≤1% (vertical mills can perform both drying and grinding).

• Iron Removal: A magnetic separator removes metallic impurities, protecting the grinding equipment.

2. Grinding System (Core Process)

| Equipment Type | Advantages | Applicable Scenarios |

| Vertical Roller Mill | Low power consumption (~40 kWh/t), small footprint | Medium- to large-scale production lines (annual output ≥ 300,000 tons) |

| Ball Mill | Low investment, easy maintenance | Small production lines or projects with limited budgets |

Process Comparison:

• Vertical Mill System: Integrated drying and grinding, high efficiency, but requiring a larger equipment investment.

• Ball Mill + Classifier: Requires a dryer and is suitable for applications requiring less fineness.

3. Finished Product Collection and Storage

• High-Efficiency Bag Dust Collector: Dust emissions ≤ 20mg/m³, meeting environmental requirements.

• Automated Packaging System: Supports bulk and pallet shipments, reducing labor costs.

Advantages of Slag Grinding Production Line

The advantages of slag grinding lines are primarily reflected in the following aspects:

1.High Production Efficiency: slag grinding production line offer high throughput, with a single unit reaching up to 70 tons per hour, making them suitable for large-scale production. Furthermore, the production line offers low maintenance costs, a long equipment life, and ease of maintenance.

2.Environmentally Friendly: The slag grinding production line utilizes a sealed design and dust removal system to effectively reduce dust and noise pollution, meeting environmental requirements. Furthermore, the line operates with low noise levels, below 60-70 decibels, meeting environmental standards.

3.High Automation: The slag grinding line utilizes an automated control system, enabling real-time monitoring and intelligent adjustment of the production process, improving production efficiency and product quality. Some equipment also supports remote control, simplifying operation and reducing labor costs.

4.High Resource Utilization: The slag grinding line converts industrial waste into valuable building materials, achieving resource recycling and reducing environmental pollution. As a concrete admixture, slag powder improves concrete’s strength, durability, and workability.

5.Wide range of applications: The slag powder grinding line is not only suitable for the production of slag micropowder, but also for the grinding of river pebbles, carbon powder, phosphogypsum, metal powder and other materials, with a wide range of applications.