Raymond Mill Working principle

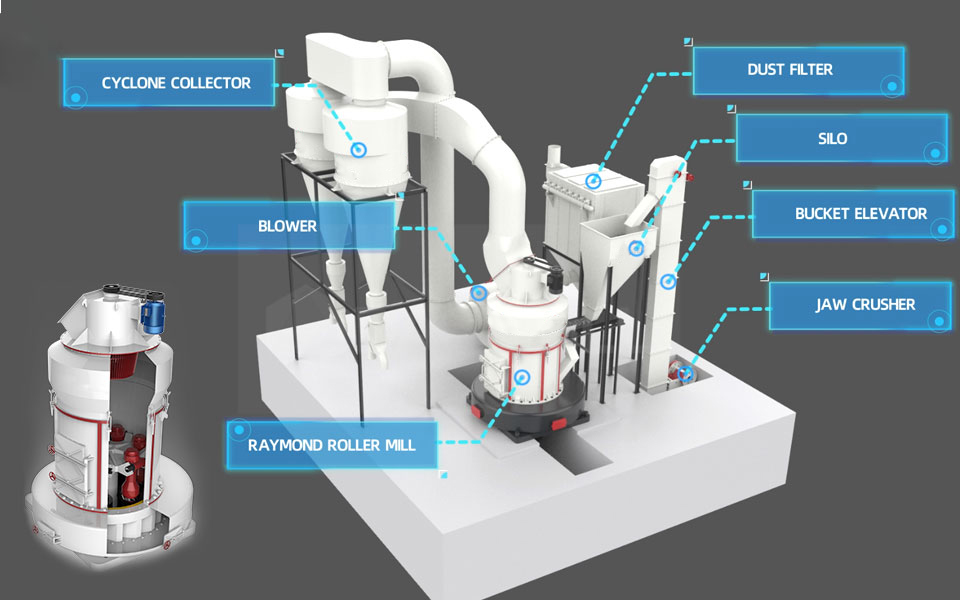

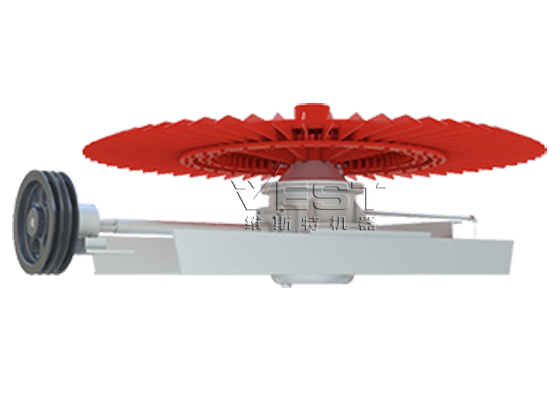

The Raymond mill is widely used in the production of mineral and coal powders. Its operating principle is that the grinding rollers roll tightly against the grinding rings under the action of centrifugal force. The material is fed by scrapers between the rollers and the grinding rings, where it is crushed into powder under the crushing pressure. A fan then lifts the powdered material and screens it through an analyzer. Material that meets the required fineness passes through the analyzer, while substandard material returns to the grinding chamber for further grinding. Finally, material that passes through the analyzer enters a cyclone separator for collection.

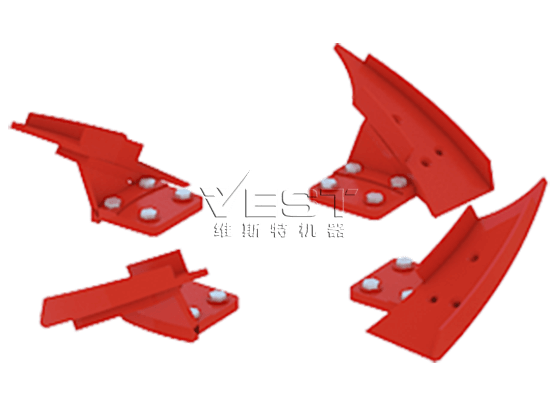

The Raymond mill’s structure includes the main unit, analyzer, piping, blower, product cyclone separator, jaw crusher, bucket elevator, electromagnetic vibrating feeder, and electronically controlled motor. The scraper system plays a crucial role in operation. Located at the lower end of the grinding rollers, the scraper rotates with the rollers, scooping up the material and feeding it between the rollers and the grinding rings, forming a cushion layer. The rotating rollers generate an outward pressure on this layer, crushing the material and achieving the desired powder production.

Raymond mill advantage

-

Uniformity of powder

-

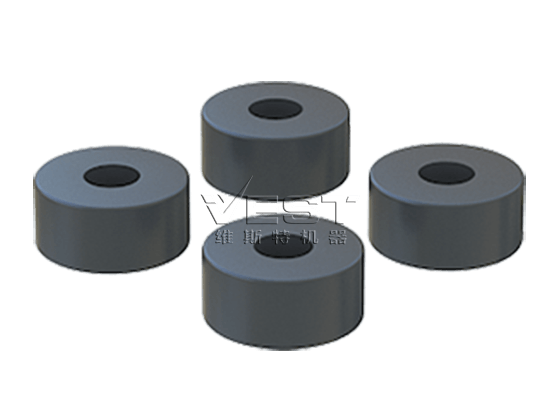

The finished powder has a consistent fineness and a sieving rate of 99%. When the grinding roller and the grinding ring reach a certain level of wear, adjust the length of the high-pressure spring to maintain a constant grinding force between them.

-

High wear resistance

-

The important components are all made of high-quality steel, the wear-resistant parts are all made of high-performance wear-resistant materials, and the machine transmission device uses a closed gear box and pulley, ensuring smooth transmission and reliable operation.

-

Easy to maintain

-

The electrical system adopts intelligent centralized control, allowing the grinding workshop to achieve unmanned operation. The operation is simple, and the maintenance of common faults is convenient.

Maximino

From Saudi Arabia

"VEST mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider VEST is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"VEST has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a VEST grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to VEST mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves VEST’s ‘Built for Decades’ promise."