SOLUTION

Quartz Processing Plant | 5 things you need to know

Processing Overview

Quartz is a mineral with a Mohs hardness of 7, typically occurring as a colorless, translucent, or transparent substance. Raw quartz ore undergoes primary and secondary crushing to produce standard quartz sand. At the VEST quartz processing plant, the quartz sand undergoes further deep grinding to become high-purity quartz powder, also known as refined quartz sand.

Due to its excellent physical and chemical properties, quartz powder is widely used in various industries, including electronics, ceramics, glass, coatings, and building materials.

The VEST quartz powder processing line systematically processes raw quartz ore into fine powder, encompassing key processes such as crushing, grinding, and grading. The graded powder can then undergo further secondary grinding to meet even finer particle size requirements.

VEST Integrated Quartz Powder Processing Plant: Efficient and Stable Process Flow

Processing raw quartz ore into fine powder typically involves four core stages: preparation, crushing, grinding, and grading. VEST’s integrated production line fully covers the entire process, offering simple operation and stable, efficient performance. The following comprehensive introduction will help you better plan your quartz powder production business.

1. Raw Material Preparation:

The raw quartz ore, transported from the quarry, first undergoes rigorous screening to remove impurities, followed by thorough cleaning to effectively remove adhering dust and other contaminants, ensuring the purity and quality of the final product from the source.

2. Crushing Stage:

The cleaned and dried quartz blocks are fed into a jaw crusher for primary crushing. Subsequently, depending on the required particle size, a hammer crusher or cone crusher can be selected for secondary crushing until the material is processed to the ideal size for the grinding process.

3. Grinding Stage:

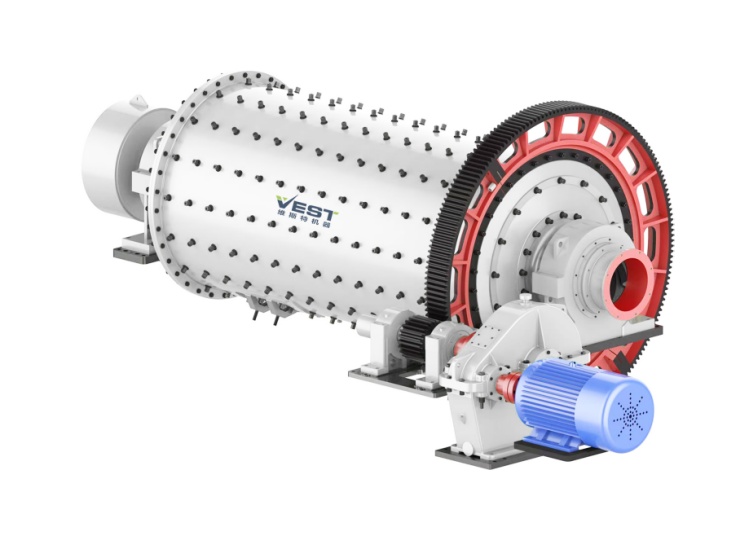

The crushed quartz is evenly fed into the grinding system via a feeder. To ensure continuous production, the production line is equipped with an intermediate silo for temporary material storage. VEST offers a variety of grinding equipment options: widely used ball mills, known for their stable performance and preferred by most customers; and high-efficiency Raymond mills, available to meet specific needs for varying output and fineness requirements.

4. Classification and Collection:

The ground powder enters a high-efficiency classifier, where it is precisely separated into qualified fine powder and coarse powder that needs to be returned for regrinding. This closed-loop design ensures optimal powder particle size and production efficiency. Finally, the qualified fine powder is collected by a dust collector and stored in the finished product silo. The entire process involves extremely low dust emissions, achieving clean and environmentally friendly production while avoiding waste.

How does VEST provide customized solutions for your quartz processing plant?

The quality of quartz powder directly depends on the efficiency and precision of the processing equipment. VEST’s advanced quartz powder production line solutions, based on their superior design and reliable performance, can be tailored to your specific needs, ensuring your project consistently produces high-purity, uniformly sized, and extremely low-impurity quartz powder.

Customized Crushing Stage Configurations:

Jaw crushers are widely used primary crushing equipment, efficiently processing large quartz ore. To meet the stringent feed size requirements of subsequent grinding equipment (typically less than 30mm), we can flexibly configure hammer crushers or cone crushers for secondary crushing, ensuring the supply of size-compliant raw materials for the grinding stage.

Grinding Solutions to Meet Diverse Finished Product Needs:

Ball Mills : This is the most popular general-purpose grinding equipment, suitable for producing quartz powder with a D97 range of 5 to 200 microns. The feed size requirement is less than 4 mm. VEST offers ball mills of various capacities to precisely match your production needs.

Raymond Mill : If your target product is coarse powder of 40-180 microns, the Raymond mill is a more economical and efficient option. This equipment can handle larger feed sizes of 25-30 mm and boasts an exceptional throughput of up to 99%, a significant advantage that many other grinding equipment struggle to match.

| Feature | Ball Mill Machine | Raymond Mill Machine |

| Main Application | Fine and ultra-fine quartz powder production | Coarse and medium quartz powder production |

| Finished Powder Fineness (D97) | 5 – 200 microns | 40 – 180 microns |

| Feeding Size | ≤ 4 mm | ≤ 25–30 mm |

| Production Capacity | Wide range of models for small to large scale | Medium capacity, ideal for lower-cost operations |

| Passing Rate | Up to 98% | Up to 99% |

| Energy Consumption | Higher due to fine grinding process | Lower due to coarser output |

| Price Range | Higher investment, higher precision | More economical option |

| Best For | High-purity, ultra-fine quartz powder production lines | Cost-effective coarse quartz powder grinding |

VEST Quartz Powder Processing Plant Core Advantages

In today’s industrial sectors heavily reliant on high-purity quartz powder, VEST, as a professional powder grinding system supplier, is helping global customers meet the dual challenges of efficiency and quality with its advanced production solutions.

Stable and Reliable Product Quality

Utilizing a PLC central control system, production parameters are monitored and adjusted throughout the entire process.Precise control of finished product particle size and capacity ensures high batch-to-batch consistency, meeting the requirements of high-end industries such as electronics and ceramics.

Significantly Reduced Energy Consumption

Equipped with advanced technology and optimized design, the equipment boasts high energy efficiency.Reducing electricity consumption at the source effectively controls long-term operating costs.

Excellent Environmental Protection and Clean Production

Equipped with a high-efficiency dust collector, effectively collecting finished powder and significantly reducing dust pollution in the workshop.Creating a clean working environment and reducing equipment wear and downtime caused by dust.

Highly Integrated and Simplified Processes

Providing integrated equipment for the entire process from crushing and grinding to collection, eliminating the need for multiple procurements.Integrated PLC control makes the entire line operation simple and intuitive, greatly improving management efficiency.

Choosing VEST is not just about selecting equipment; it’s about choosing an efficient, reliable, and future-oriented production model. We cordially invite you to contact us to discuss and tailor a grinding solution with exceptional cost-effectiveness tailored to your needs.

Why Choose VEST as Your Quartz Powder Processing Partner?

VEST, with its professional technical equipment and comprehensive service support, is committed to becoming your trusted partner for quartz powder production solutions. Choosing us means you will gain the following core advantages:

1. Superior Products: Precise Particle Size Control

VEST production lines can stably produce ultrafine quartz powder ranging from approximately 5 to 200 microns. We offer precise fineness adjustment functions to ensure that the finished powder perfectly meets the specific needs of your different application scenarios.

2. Advanced Technology: Flexible and Efficient Grinding Solutions

We employ cutting-edge grinding technologies to optimize equipment performance. You can flexibly choose equipment based on your target products: ball mills are suitable for fine powders of 5-200 microns; if the requirement is in the range of 40-180 microns, Raymond mills can achieve high-efficiency output with a more economical investment.

3. Customized Solutions: Deeply Aligned with Industry Needs

Whether your products will be used in glass ceramics, electronic solar energy, architectural coatings, or foundry refractory materials, VEST can tailor solutions for you. We design customized process flows and equipment configurations based on your specific requirements for fineness, capacity, and purity.

4. Comprehensive Support: Worry-Free Operational Guarantee

Choosing VEST means comprehensive service support. Our engineering team will provide end-to-end services from production line installation and system commissioning to operator training, ensuring your team can operate and maintain the system proficiently, guaranteeing production continuity and stability.

Key Factors Affecting the Construction and Operating Costs of Quartz Processing Plants

Constructing a quartz processing plant requires comprehensive consideration of multiple cost components. The following are the main influencing factors:

1. Plant Scale and Capacity

The plant’s design scale and production capacity are fundamental determinants. Larger scale and higher capacity require increased investment in machinery, infrastructure, and land area, directly driving up overall investment costs.

2. Equipment Configuration and Automation Level

Quartz processing involves multiple processes such as crushing, grinding, washing, and grading. Equipment procurement costs are primarily influenced by capacity targets and the degree of automation. For example, the initial investment for a fully automated production line with advanced control systems is typically higher than that for semi-automatic or manually-intensive systems.

3. Geographical Location and Infrastructure Conditions

Site selection is crucial for cost control, and the following aspects should be carefully evaluated:

- Raw Material Proximity: Proximity to quartz mines significantly reduces raw material transportation costs.

- Utility Support: Stable and reliable power, water, and natural gas supplies are prerequisites for continuous plant operation.

- Land Costs: Land prices vary significantly by region, generally higher in cities and industrial areas than in remote areas.

- Logistics Convenience: Convenient road, rail, or port access helps reduce logistics costs for shipping finished products.

4. Human Resources and Skills Structure

Labor costs are influenced by both regional wage levels and job skill requirements. For example, skilled technicians who can operate and maintain advanced automated equipment typically have higher labor costs than general operators.

5. Environmental Compliance and Sustainability Requirements

Complying with local environmental regulations and obtaining the necessary permits are essential for the legal operation of a factory. Meeting emission standards often requires additional investment in pollution control equipment, wastewater treatment, and solid waste management systems; these compliance costs constitute a significant portion of the total cost.