SOLUTION

Quartz Powder Processing Plant

Processing Overview

Quartz is a common silicate mineral with a wide range of industrial uses. It is processed into granular quartz sand (silica sand) and finer quartz powder. Quartz powder is favored in the market for its finer particle size (over 120 mesh) and higher purity.

What are the processes involved in a Quartz Powder Processing Plant?

Typically, turning quartz into fine powder requires four stages: preparation, crushing, grinding, and grading. Here, you can gain a deeper understanding of these detailed processes and their functions. This will help you establish your own silica powder processing plant business.

Raw Material Preparation:

Quartz raw materials are mined from the quarry and carefully screened to remove impurities. They are then cleaned to remove dust and contaminants. This ensures the quality of the final powder.

Crushing:

After drying and cleaning, the quartz is fed into a jaw crusher for primary crushing. This equipment breaks the material into small pieces. You can also use a hammer crusher or cone crusher for secondary crushing. These steps reduce the material to the desired feed size for grinding.

Grinding:

Our quartz powder production line is equipped with a feeder to feed the crushed quartz into the grinder. We also provide a feed silo for material storage. VEST offers three types of grinding mills for your selection. The ball mill is the most popular equipment among our Quartz Powder Processing Plant customers. Depending on your needs, you can also choose our Raymond mill for pulverizing.

Classification:

After grinding, the quartz powder enters the classification process. The VEST high-efficiency classifier separates the quartz powder into qualified fine powder and coarse powder. Unqualified fine powder is returned to the grinding equipment for re-grinding. Qualified fine powder is collected in the product silo. The equipment is equipped with a dust collector to collect fine powder, avoiding pollution and waste.

Which quartz grinder is right for your Quartz Powder Processing Plant?

A quartz grinder is a key piece of equipment in a quartz powder production line.

The following grinder features can help you quickly make a selection.

| Equipment | Ball Mill | Raymond mill | Vertical Roller Mill |

| Price | High | Low | High |

| Fineness | Coarse powder | Fine powder | Fine powder |

| Yield | High | Normal | Normal |

| Common Applications | Ores, cement | Non-flammable and non-explosive non-metallic materials | Cement clinker, slag, coal powder |

In addition, you can choose the appropriate grinder based on the particle size and properties of the grinding product.

Based on product particle size: Ball mill (20-200 mesh), Raymond mill (80-325 mesh), Vertical roller mill (20-400 mesh).

Based on material properties: For materials with higher hardness, ball mills and Raymond mills are recommended; for materials with medium hardness, high moisture content, and high viscosity, a Vertical roller mill is recommended. Next, let us take a detailed look at the advantages of these three quartz grinders.

1. Quartz Ball Mill

The ball mill is equipped with ceramic balls, effectively preventing iron contamination and improving product purity when processing quartz powder.

Feed size: ≤25mm

Discharge size: 20-200 mesh

Production capacity: 0.65–615 tons/hour

Suitable for dry or wet grinding of quartz.

Maximum output reaches 615 tons/hour, enabling continuous production.

Easy installation and adaptable to harsh environments.

2. Quartz Raymond Mill

The Raymond mill is a highly efficient fine grinding machine suitable for large-scale production of quartz powder.

Feed size: ≤30mm

Discharge size: 80-325 mesh

Production capacity: 8-176 tons/shift (8 hours)

The Raymond mill boasts a screening efficiency of up to 99%.

Its low investment and power consumption reduce production costs.

High automation reduces machine failure rates and minimizes labor costs. Excellent sealing performance ensures low noise and pollution levels.

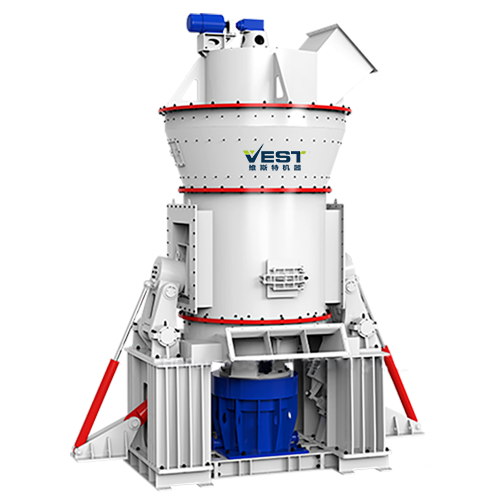

3. Quartz Vertical Roller Mill

Vertical roller mills occupy less floor space, making them ideal for space-constrained quartz grinding plants and helping to reduce operating costs.

Feed size: ≤55 mm

Discharge size: 20-400 mesh

Capacity: 2–420 tons/hour

Hydraulic control reduces power consumption by 30%–50% compared to ball mills.

Occupancy is only 50% of that of traditional ball mills, reducing construction costs.

The fully automatic control system allows for remote operation.

Why choose VEST Quartz Powder Processing Plant?

In today’s competitive industrial environment, efficient production of high-purity quartz powder is crucial for many industries. Quartz powder plays a key role in electronics, glass, ceramics, and construction.

As an experienced supplier of grinding machinery, VEST has provided professional silica sand production solutions to numerous clients. For your quartz powder production needs, VEST offers a complete production line featuring advanced technology, reliable performance, and customized systems.

High-quality grinding mills for premium quartz powder:

With the VEST quartz powder processing plant, you can obtain ultrafine quartz powder ranging from approximately 5 to 200 microns. The fineness of the quartz powder can be adjusted to suit different quartz powder applications.

Advanced Grinding Technology:

VEST utilizes the latest grinding systems for optimal performance. Ball mills can produce fine powders ranging from 5 to 200 microns. Raymond mills are more affordable and can meet your needs if you only need powders ranging from 40 to 180 microns. Furthermore, air classifiers are equipped to ensure uniform particle size distribution.

Customized Solutions for Different Industries:

Whether you need quartz powder for glass and ceramics, electronics and solar energy, construction and coatings, or foundry and refractories, the VEST quartz powder production line can meet your needs. We can customize your grinding equipment based on your fineness, output, and purity requirements.

Fully Automatic Intelligent Control:

The VEST quartz powder processing plant uses a PLC control system for real-time operation and monitoring of the powder production process. This makes the entire production process easy to control. The PLC control system also allows for easy adjustment of parameters such as particle size, output, and grading.

Reliable After-Sales Support:

With VEST, you don’t have to worry about installation, training, or maintenance. Our professional engineers can help you install the entire production line. We also provide online and on-site training services to ensure your workers can operate the entire line smoothly.

If you are looking for a high-purity, ultra-fine silica sand processing plant, please contact VEST today. Daswell Machinery provides you with advanced, efficient, customized grinding solutions. We promise excellent product quality and highly competitive production costs.