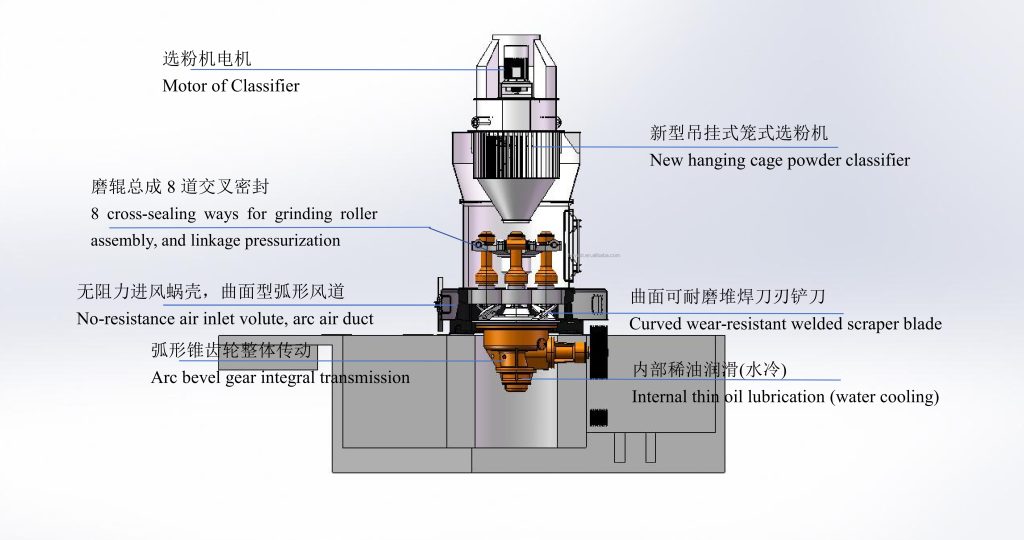

MTM Grinding Mill Working principle

The raw materials that meet the feeding requirements are sent to the raw material warehouse by the forklift, and then the variable frequency belt feeder will evenly and continuously convey material into the main machine grinding chamber of MTM Grinding Mill for grinding. The ground powder will raised by the blower airflow, after being classified by the cage classifier, standard powder flows into the bypass cyclone collector to be separated and collected, solenoid valve discharges standard powder. Airflow is inhaled in the air blower through the return duct upon bypassing the cyclone collector. The Whole flow air system is closed recirculation, and it flows in positive and negative pressure.

Advantages

- Cost-effective Investment

- MTM Grinding Mill features an integrated system, requiring minimal investment in construction and foundation for transforming bulk materials into finished powder.

- Energy Saving

- MTM has an energy consumption of more than 60% lower than that of the same grade of ball mill under ideal working conditions.

- High Efficiency

- MTM trapezium grinding mill adopts high efficiency impeller fan, which improves the efficiency of air induction from 62% to 85%.

- Worry-free Operation

- VEST can offer customers technical services about products and original spare parts to ensure the worry-free operation.

Maximino

From Saudi Arabia

"VEST mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider VEST is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"VEST has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a VEST grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to VEST mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves VEST’s ‘Built for Decades’ promise."