SOLUTION

Limestone Grinding Mill Production Line

Processing Overview

Process flow diagram

Introduction of Slag Grinding Production Line

Limestone is a common sedimentary rock primarily composed of calcium carbonate (CaCO₃). It is commonly found in shallow marine sediments formed by biological debris. Its physical properties include a hardness of approximately 3 and a density of 2.6-2.9. Due to its composition and properties, limestone of varying fineness has different uses.

Uses of limestone powder

| Fineness | Limestone Powder Applications |

| Coarser than 200 mesh | Lightweight bricks, soil conditioners, etc. |

| 200-325 mesh | Desulfurization powder, cement, glass, chalk, etc. |

| 400-800 mesh | Rubber, plastics, sealants, chemicals, toothpaste, etc. |

| 1250-1500 mesh | Paints, stationery, cables, cosmetics, pharmaceuticals, etc. |

| 2000-3000 mesh | High-end papermaking, high-end PVC, high-end fillers, high-end silicone, etc. |

Detailed Process Flow of a Limestone Grinding Mill Production Line

1. Raw Material Pretreatment

• Crushing: Large pieces of limestone are initially crushed by jaw crushers, impact crushers, and other equipment to achieve a particle size suitable for subsequent grinding.

2. Grinding System (Core Process)

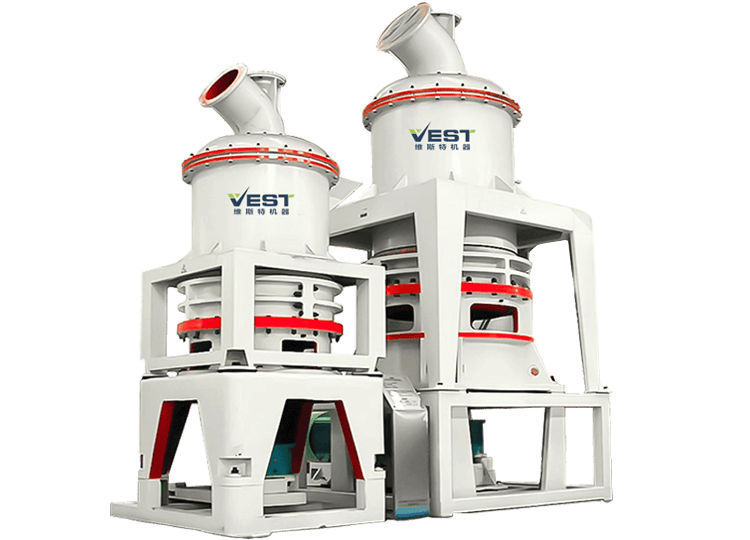

I. YGM Ultrafine Grinding Mill

• Applicability : The YGM Ultrafine Grinding Mill is suitable for ultrafine grinding of high-hardness materials (such as limestone, quartz, and high-hardness ores), with a grinding fineness range of 325-2500 mesh, making it ideal for limestone powder production with high fineness requirements.

• Advantages : High output and high fineness make it suitable for large-scale continuous production and for large-scale limestone grinding production lines.

• Application Scenarios : Suitable for industries requiring high-fineness limestone powder, such as cement, chemicals, and environmental protection.

II. Raymond Mill

• Applicability : The Raymond Mill is suitable for grinding medium-hardness materials (such as limestone, gypsum, and ores), with a grinding fineness range of 80-400 mesh, making it suitable for small and medium-sized production.

• Advantages : Simple structure, easy operation, and low maintenance costs make it suitable for small and medium-sized enterprises and small- and medium-sized limestone grinding production lines.

• Application Scenarios : Suitable for small and medium-sized limestone grinding mill production line, suitable for small and medium-sized enterprises or initial investments.

III. Vertical Grinding Mill

• Applicability : Vertical grinding mills are suitable for grinding high-hardness materials (such as limestone, cement, and ore), with a grinding fineness of up to 3000 mesh and above, suitable for high-fineness and high-volume production needs.

• Advantages :High integration, high output, and excellent environmental performance make them suitable for large-scale limestone grinding production lines.

• Application Scenarios : Suitable for large-scale limestone grinding mill production lines, suitable for large enterprises or those with high-volume production needs.

3. Finished Product Collection and Storage

• High-Efficiency Bag Dust Collector: Dust emissions ≤ 20mg/m³, meeting environmental requirements.

• Automated Packaging System: Supports bulk and pallet shipments, reducing labor costs.

Advantages of Limestone Grinding Mill Production Line

The advantages of Limestone Grinding Mill Production Line are primarily reflected in the following aspects:

• Leading Technology: This limestone grinding mill production line features advanced technology, integrating crushing, drying, grinding, powder selection, and conveying.

• High degree of automation: The fully automatic control system features a chain mechanism that allows for remote control and simple operation.

• Low Operating Costs: The system utilizes a thin oil automatic forced lubrication system and is equipped with a hydraulic roller tilting device. This allows the roller to be hydraulically tilted out of the machine for maintenance, providing ample access for easy maintenance and low operating costs.

• Efficient and Environmentally Friendly: The entire system operates under negative pressure and utilizes a high-efficiency pulse dust collector to collect dust. This ensures dust-free production line, meeting the latest environmental standards.