SOLUTION

Kaolin Grinding Mill Production Line

Processing Overview

What is kaolin?

Along with mica, quartz, kaolin, and calcium carbonate, kaolin is considered one of the four major non-metallic minerals. Kaolin is a white clay composed of aluminum silicate. Due to its white and fine appearance, it is also called white clay or porcelain clay.

Natural kaolin can be divided into three industrial types: hard kaolin (earthy), soft kaolin, and sandy kaolin, depending on its origin, properties, plasticity, and sand content (minerals with particle sizes greater than 50μm, such as quartz, feldspar, and mica).

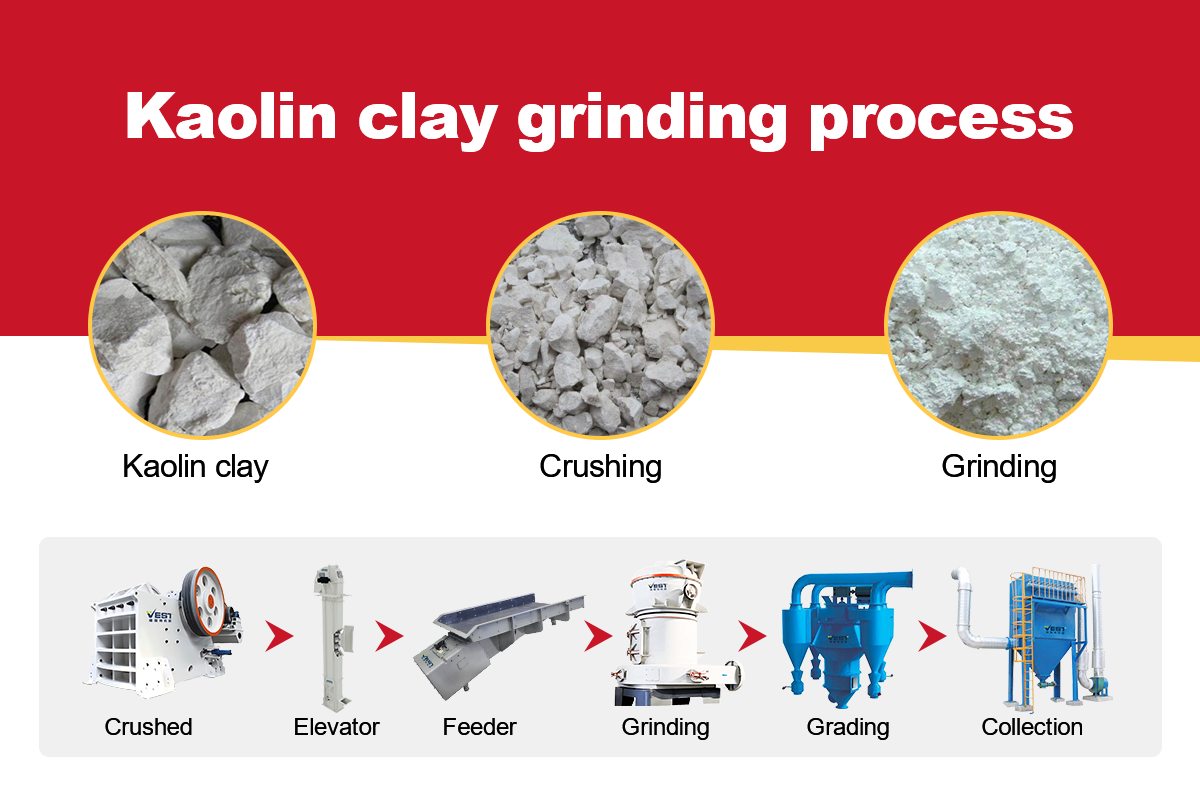

Process flow of kaolin grinding mill production line

• Crushing : A jaw crusher is used to break large kaolin lumps into smaller pieces, typically ranging from 15mm to 30mm.

• Crushing : A jaw crusher is used to break large kaolin lumps into smaller pieces, typically ranging from 15mm to 30mm.

• Grinding (a key step) : A Raymond mill or YGM mill is used to grind the material into a fine powder.

• Classification : The resulting fine powder is passed through a classifier to ensure compliance with the specified particle size requirements.

• Collection : The finished powder is fed to a powder collection system for collection.

3 Recommended Kaolin Grinding Mills

The finer the finished product, the higher its economic value. Therefore, grinding is crucial. How do you choose the best kaolin grinding mill?

| Powder Fineness Range | Production Requirement | Recommended Grinding Equipment | Application Scenarios |

| 325 mesh or less | General | Raymond Mill | General fineness requirements, low to medium production |

| 150-2500 mesh | Medium | YGM Raymond Grinding Mill | Medium fineness, medium production |

| 150-3000 mesh | High production | Vertical roller mill | High fineness, high production line |

1. Raymond Mill

• Simple Structure and Easy Operation : This equipment features a relatively simple structure, making it easy to operate and maintain, making it suitable for small and medium-sized enterprises or users with low technical requirements.

• Low Cost : Compared to other grinding equipment, the Raymond mill has lower initial investment and operating costs, making it suitable for users with limited budgets or low production requirements.

• Application : Non-flammable and explosive non-metallic ores with a Mohs hardness of less than 9, such as kaolin, quartz, and limestone.

2. YGM Raymond Grinding Mill

• Medium Fineness and Output : This equipment can meet production needs for medium fineness and medium output, suitable for processing a variety of materials.

• Stable Operation and Reliable Performance : This equipment offers stable performance and reliable operation, making it suitable for medium-scale production.

• Application : Non-flammable and explosive non-metallic ores with a Mohs hardness of less than 7, such as kaolin, quartz, and talc.

3. Vertical Roller Mill

• High Output and High Efficiency : This equipment offers high output, making it suitable for large-scale production and meeting the needs of both high output and high fineness.

• Low energy consumption and high efficiency : Compared to other grinding equipment, vertical roller mills offer lower energy consumption and higher efficiency, making them suitable for large-scale production.

• Application : Non-flammable and non-explosive non-metallic ores with a Mohs hardness of less than 7, such as kaolin, quartz, and limestone.

Advantages of Kaolin Grinding Mill Production Line

1. Long Service Life of Wearing Parts:

The grinding rollers and grinding rings are forged from special materials, significantly increasing their utilization. Given the same material and finished product fineness, their service life typically exceeds one year. When processing calcium carbonate and calcite, the service life can reach 2-5 years.

2. Low Investment Cost:

The Kaolin grinding plant integrates crushing, drying, grinding, grading, and conveying, resulting in a simple, compact layout and minimal footprint. Furthermore, it can be deployed outdoors, significantly reducing investment costs.

3. High Grinding Efficiency:

The grinding rollers directly crush the material onto the grinding disc, resulting in low energy consumption, saving 30%-40%.

Please feel free to contact us for more information!