CASE

Malaysia 200-325 mesh kaolin grinding production line

Introduction

I. Project Background

As one of Southeast Asia’s leading mineral resource countries, Malaysia boasts abundant kaolin resources, widely used in industries such as ceramics, papermaking, coatings, and chemicals. In recent years, with industrial development and increasing market demand, kaolin processing and grinding capabilities have continued to improve. In recent years, Malaysia has also steadily advanced the construction of kaolin grinding production lines to meet domestic and international demand for kaolin powder products.

II. Project Overview

1. Project Name

Malaysia Kaolin Grinding Production Line Project

2. Project Scale

Capacity: 10-15 tons/hour

Product Type: Kaolin Powder

Applications: Ceramics, Papermaking, Coatings, Chemicals, etc.

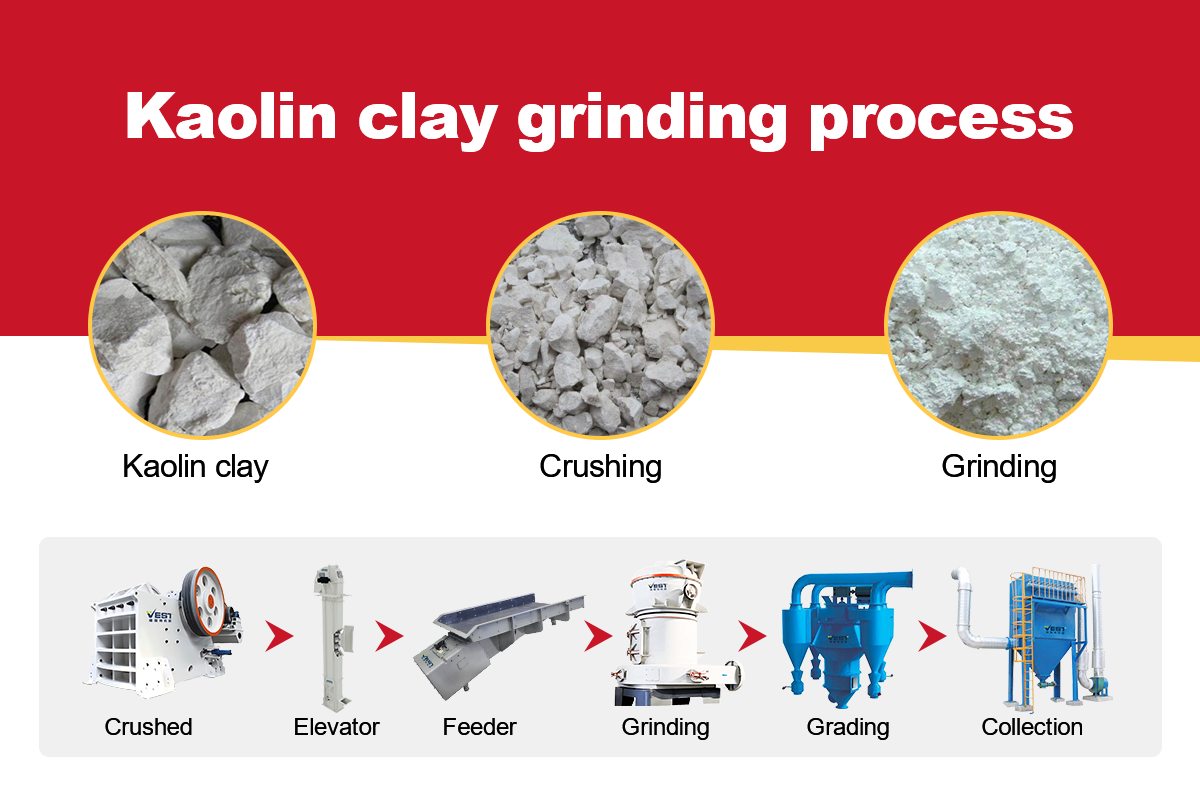

III. Kaolin Grinding Process

Based on the client’s needs, we customized a production line that met their production and product requirements. Below are the specific details of the kaolin grinding production line:

1. Equipment Selection

Since the client’s requirements for the finished product mesh size were relatively low (200-325 mesh), we recommended a Raymond mill as the key grinding equipment.

| Features | Price | Maximum feed size | Production capacity | Finished fineness |

| Lowest Price in 2025 | ≤30mm | 0.6-78t/h | 80-325 mesh |

Equipment Advantages:

Mature technology, stable and reliable, low investment cost, and relatively low energy consumption. It is the most economical and common choice for processing materials in the 100-325 mesh range. It occupies a relatively small footprint. Its vertical structure provides a robust system and stable performance.

Energy-saving and energy-efficient: Utilizes advanced grinding technology to improve grinding efficiency and reduce energy consumption.

Environmentally friendly design: Equipped with a dust removal system to reduce dust pollution.

Automated control: Automated control of the entire process improves production efficiency and safety.

2. Kaolin Grinding Production Line Process

Crushing: Kaolin is fed into a jaw crusher and crushed to a feed fineness suitable for the mill (15mm-30mm).

Crushing: Kaolin is fed into a jaw crusher and crushed to a feed fineness suitable for the mill (15mm-30mm).

Grinding: The crushed kaolin is conveyed by an elevator to a storage hopper, where it is fed by a feeder into the grinding mill for grinding.

Classification: The ground material is classified by a classifier, and unqualified powder is returned to the main machine for re-grinding.

Collection: Powder that meets the required fineness is collected by the airflow through a pipeline into a powder collection system. The finished powder is then delivered to the finished product silo.

IV. Project Implementation and Operational Results

1. Project Implementation Process

The project, from equipment selection and procurement, installation and commissioning to trial operation, took approximately 6-8 months.

The project is implemented by the company’s professional engineering personnel, ensuring the quality of equipment installation and the rationality of the process flow.

2. Operational Results

Productivity Achieved: Actual production capacity reached over 90% of the designed capacity, meeting market demand.

Stable Product Quality: The product particle size distribution is uniform and meets industry standards.

Significant Economic Benefits: After commissioning, the project will process approximately 100,000 tons of kaolin raw materials annually, significantly increasing annual sales revenue.

If your goal is to produce low- to mid-range fillers for ceramics and refractories, a Raymond mill kaolin grinding production line is the most economical and affordable solution, with a product fineness of 200-325 mesh.

If your goal is to enter the papermaking or high-end coatings markets, a vertical mill is recommended, with a product fineness of 600-1250 mesh.

If your target is ultra-high value-added fields such as cosmetics, pharmaceuticals, and high-end functional materials, a YGM Raymond mill system is essential to produce ultrafine powders with a fineness of 2500 mesh or higher.