CASE

Indonesia 20-25TPH Limestone Grinding Production Line

Introduction

I. Project Background

In Indonesia, the demand for high-purity limestone powder is growing with the development of industries such as construction, cement, and chemicals. However, Indonesia’s local limestone processing capacity is currently limited, with heavy reliance on imports, resulting in high costs and inconsistent quality. Therefore, the client sought to build a local limestone grinding production line to process resources locally, increase product value, and enhance market competitiveness.

II. Project Overview

1. Project Name

Indonesia limeston Grinding Production Line Project

2. Project Scale

Capacity: 20-25 tons/hour

Product Type: Limeston Powder

Applications: Construction, cement, chemicals, industrial raw materials and other fields.

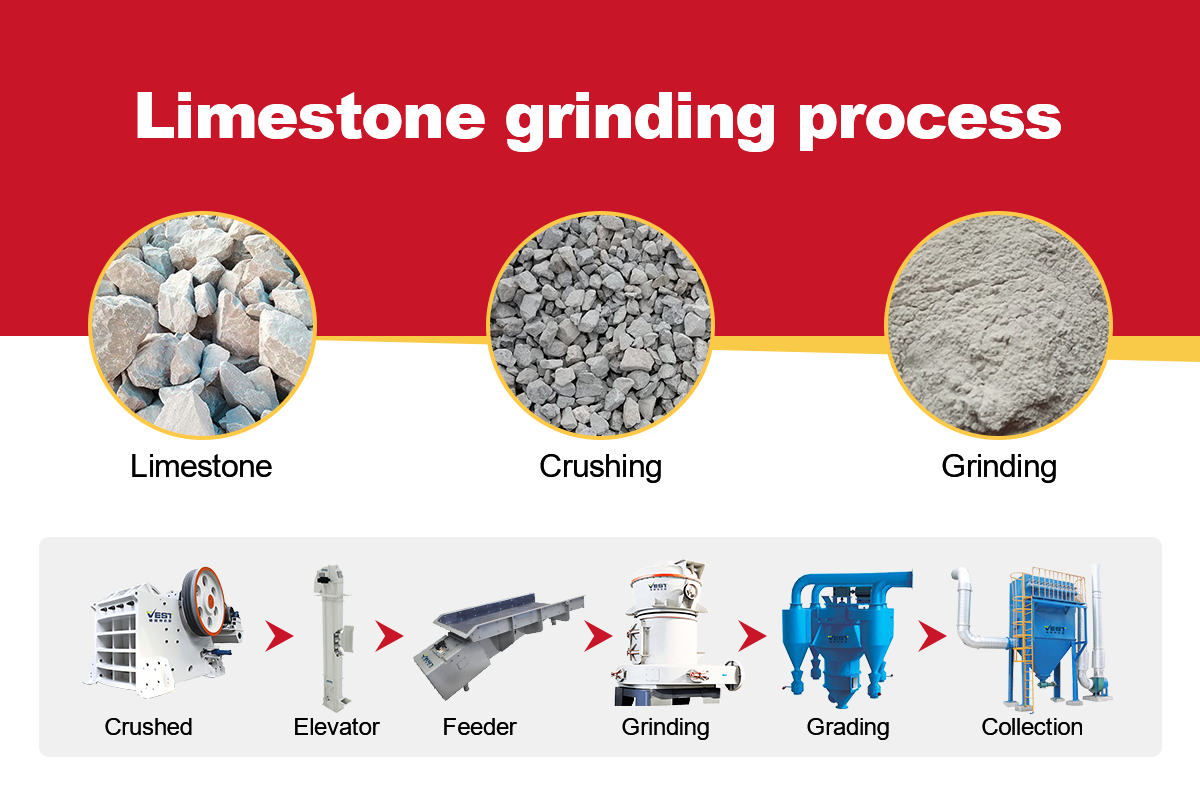

III. Kaolin Grinding Process

This Limestone Grinding production line is mainly used in the fields of construction, cement, chemicals, industrial raw materials, etc. Customers have high requirements for product purity, particle size, and stability. Customers hope that the equipment has the characteristics of high efficiency, low energy consumption, and high degree of automation.

Based on customer requirements, the key equipment in the Limestone Grinding production line includes:

Crushing Equipment: Jaw crushers and impact crushers for crushing large limestone lumps to a suitable particle size.

Grinding Equipment: MTM European Type Trapezium Mill for grinding the crushed limestone into powder.

Classifying Equipment: High-efficiency classifiers for controlling product particle size.

Conveying Equipment: Belt conveyors and pneumatic conveying systems for material transportation.

Dust Removal Equipment: Reduces dust pollution and protects the environment.

Control System: PLC control system for automated control and remote monitoring.

The Limestone Grinding production line process is as follows:

Raw material processing: Limestone ore → Crushing → Grinding → Classification → Packaging → Finished product.

Automation: A PLC control system enables full automation of the entire process, improving production efficiency and safety.

Environmental protection: Dust removal equipment is installed to reduce dust pollution and ensure environmental friendliness.

IV.Project Achievements and Customer Feedback

Production Capacity Met: Actual production capacity reached over 90% of the designed capacity, meeting market demand.

Stable Product Quality: Product particle size distribution is uniform and meets industry standards.

Significant Economic Benefits: After commissioning, the project will process approximately 100,000 tons of limestone raw material annually, significantly increasing annual sales revenue.

Customer Feedback: Customers are satisfied with the equipment performance, product quality, and after-sales service.

When reliability and efficiency determine your material grinding operations, VEST is your trusted partner, providing cutting-edge grinding line solutions. Our high-performance grinding and crushing equipment is designed to minimize operating costs while maximizing productivity.

In addition to the machinery, our dedicated technical support team provides expert guidance tailored to your project’s unique needs, from installation to long-term maintenance. Choosing VEST means investing in a seamless blend of innovation and practicality, with every component optimized to meet demanding requirements while minimizing downtime. Trust isn’t earned through promises alone; it’s built on consistent performance, and VEST delivers that.

Before making an investment decision, provide us with a sample of your raw limestone ore. We can conduct a free pilot test and provide the most accurate equipment selection, quotation, and energy consumption estimate based on your target mesh size and output. This helps you mitigate risk and ensure a positive return on your investment.