The specific steps for producing gypsum powder using an HGM Micro Powder Mill are as follows:

A gypsum powder production line typically includes crushing, grinding, calcining, and classifying. Grinding is a crucial step, and the HGM micro-powder mill is a vital core piece of equipment.

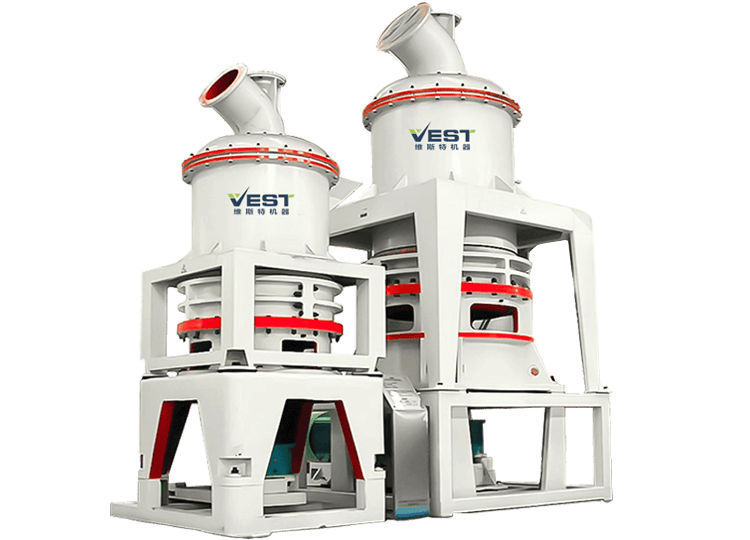

The HGM micro-powder mill is a new type of ultrafine grinding equipment designed for the ultrafine grinding of brittle materials with low to medium hardness, specifically those with a Mohs hardness of 6 or less, such as gypsum and calcium carbonate.

The HGM Micro Powder Mill can grind gypsum powder to a fineness between 325 and 3000 mesh. Its operating principle is that a motor drives the main shaft and rotating disc, causing the material to fall into the grinding ring raceway under centrifugal force. The material then passes through multiple grinding rings and is finally separated into fine powder by a classifier.

The gypsum powder production line process mainly includes the following steps:

The gypsum powder production line process primarily includes crushing, grinding, grading, collection, and packaging, among other steps, which enables the efficient production of gypsum powder products that meet your requirements.

1. Crushing: Large gypsum ore is crushed into smaller particles using a jaw crusher or impact crusher, typically with a particle size of less than 25mm. This step prepares for the subsequent grinding process. Our VEST crushing equipment can help you with these preliminary preparations, significantly improving production efficiency. (Of course, this step is optional; if your ore particle size is already small, you can skip it.)

2. Feeding: Use a suitable feeder to feed the raw gypsum into the HGM micronized powder mill. (The feed particle size must meet the mill specifications.)

3. Grinding: The motor drives the main shaft and turntable, causing the gypsum ore to fall into the grinding rings under centrifugal force. After multiple grinding cycles, the gypsum ore is finally ground into fine particles. During this process, we can adjust mill parameters (such as classifier speed and grinding pressure) to achieve your desired gypsum powder fineness.

4. Classification and Collection: The ground material is classified by a powder classifier. Unqualified coarse powder is returned to the HGM micro-powder mill for re-grinding. Qualified fine powder is separated and collected by airflow and conveyed to the finished product silo via a conveyor at the discharge port.

5. Quality Control and Packaging: The final product is tested for purity, fineness, and other specifications to ensure it meets your production requirements. An automated packaging system is also configured to package and distribute the gypsum powder as needed, improving production efficiency.

Using the HGM grinding mill in the gypsum powder production line offers several advantages:

1. High Fineness: It can produce ultrafine powders with particle sizes as low as D97 = 3-45 microns, meeting the needs of various applications.

2. High Energy Efficiency: Compared to other equipment, such as ball mills, the HGM grinding mill offers higher output, lower energy consumption, and greater efficiency, given the same fineness requirements and motor power. 3. Low Investment Cost: The HGM mill integrates grinding, crushing, drying, grading, and conveying in one machine. Its simple process flow and compact structure create a small footprint, only 50% of that of a ball mill, directly reducing investment costs.

4. Excellent Environmental Performance: The HGM mill’s system is completely sealed and operates under full negative pressure, eliminating dust leakage and creating a virtually dust-free workshop. Its low noise and vibration levels contribute to environmental protection.

5. Quality Control and Packaging: Test the purity, fineness, and other specifications of the final product to ensure it meets the required standards. Pack and distribute as needed to improve production efficiency.

No material needs to be applied to the grinding disc before startup, and the mill can be started without load, eliminating the hassle of startup. Low wear and tear are achieved, and the grinding rollers and grinding disc linings are made of special materials, ensuring a long service life.

6. Wide Range of Applications: The HGM mill is suitable for a wide range of industrial applications, including metallurgy, mining, cement, chemicals, and non-metallic minerals, and can produce ultrafine powders for a wide range of materials. These advantages make our VEST HGM mill a popular choice for fine powder production across various industries.

If you would like to learn more about our equipment specifications or require other raw materials to be ground and crushed, please feel free to contact us. Our professional technicians will provide you with one-on-one consulting services to solve your production problems.