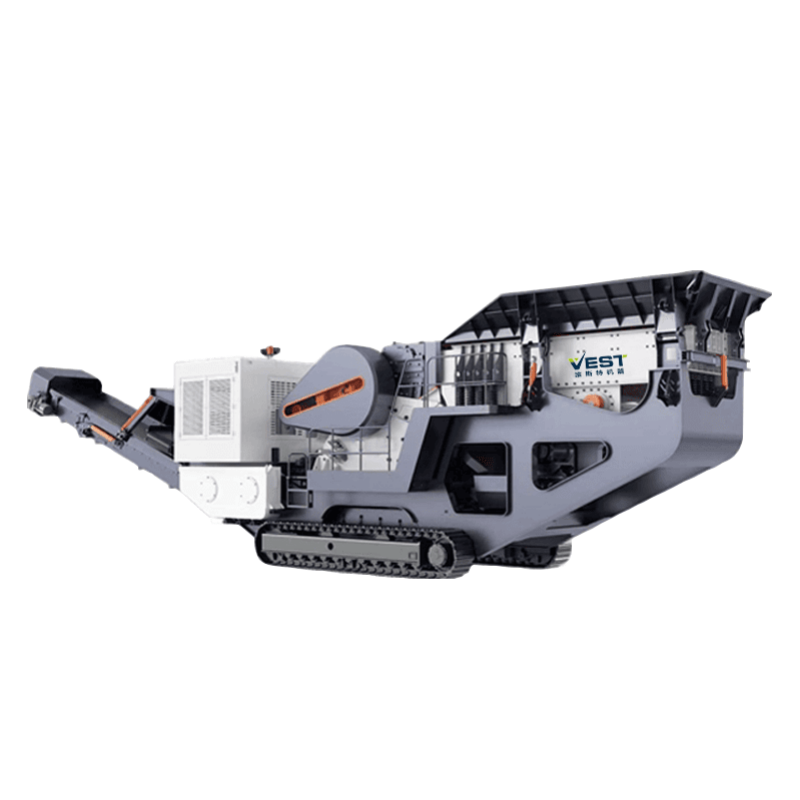

Crawler Mobile Jaw Crusher

Raw materials for processing in Crawler Mobile Jaw Crusher — Ores and minerals (metal ores such as iron ore, copper ore, lead-zinc ore, as well as non-metallic ores such as limestone, marble, granite), phosphate ore, pyrite, and fertilizer raw materials such as phosphate fertilizer and potassium fertilizer.

Are you interested in our machines? Custom Solution for your needs.Contact Us.

Crawler Mobile Jaw Crusher Details

- DATE

- APPLICATION FIELD

- Reviews (3)

*The capacity and output will vary according to different materials, feed particle size, and other factors. Please contact VEST for equipment selection for specific projects.

| VTC Crawler Mobile Jaw Crusher Plant | ||||||

| Model | TVTC96J | TVTC106J | TVTC116J | TVTC120J | TVTC1380J | TVTC130J |

| Capacity (t/h) | 100-250 | 150-360 | 200-450 | 250-520 | 210-650 | 300-750 |

| Weight (t) | 32 | 45 | 52 | 62 | 63 | 108 |

| L×W×H (mm) | 12450×2500×3100 | 14000×2800×3400 | 15600×3000×3700 | 16000×3000×3700 | 15500×3000×3600 | 19500×3500×3900 |

| Jaw Crusher | ||||||

| Model | C96 | C106 | C116 | C120 | C3054 | C130 |

| Max Feed edge (mm) | 500 | 580 | 650 | 700 | 650 | 800 |

| Motor Power (kw) | 90 | 110 | 132 | 160 | 160 | 160 |

| Vibrating Feeder | ||||||

| Model | GZT/ZSW3895 | GZT/ZSW4211 | GZT/ZSW4211 | GZT1245 | GZT1345 | GZT/ZSW1345 |

| Hopper Volume (m3) | 4 | 5 | 6 | 7 | 7 | 10 |

| Feeding Height (mm) | 3600 | 3900 | 4000 | 4400 | 4000 | 5800 |

| Motor Power (kw) | 11 | 15 | 15 | 15 | 22 | 22 |

| Belt Conveyor | ||||||

| Main Belt Conveyor (m) | B1000-12 | B1000-12 | B1200-13 | B1200-13 | B1200-13 | B1200-13 |

| Discharge Height (mm) | 3200 | 3200 | 3200 | 3400 | 3400 | 3500 |

| Motor Power (kw) | 11 | 11 | 11 | 11 | 11 | 11 |

| Side Belt Conveyor (m) | B500-3.8 | B500-3.8 | B500-3.8 | B500-3.8 | B500-3.8 | B650-4 |

| Discharge Height (mm) | 1800 | 1800 | 1800 | 2200 | 2200 | 2500 |

| Motor Power (kw) | 3 | 3 | 3 | 3 | 3 | 3 |

| Magnetic Separator(Optional) | ||||||

| Model | RCYQ-10 | RCYQ-10 | RCYQ-12 | RCYQ-12 | RCYQ-12 | RCYQ-12 |

| Motor Power (kw) | 3 | 3 | 4 | 4 | 4 | 4 |

| Dual-power Assembly | ||||||

| Driving Mode | Diesel — electricity | |||||

| Note: Crawler Mobile Jaw Crusher models, parameters, appearance, etc. are constantly being improved. If any modifications cause differences, please refer to the actual product received. | ||||||

Leave a review

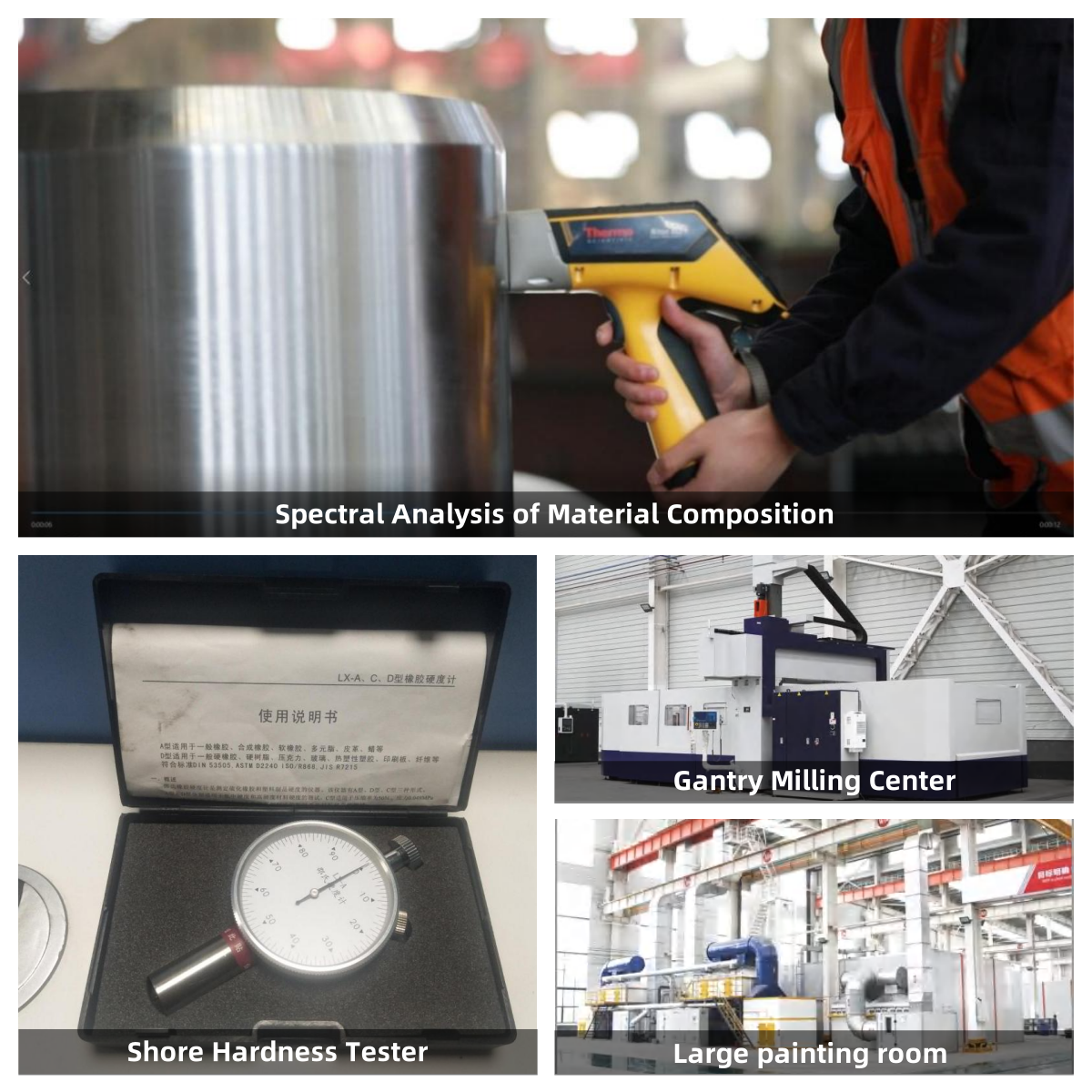

Why Choose VEST Crawler Mobile Jaw Crusher

-

High cost performancelowest price, best work return

-

High quality spare partsMn13Cr2/Mn18Cr2,long lifetime, full service system, saving costs

-

High Crushing efficiencyThe design of deep V crushing chamber adjustable final size, reliable performance, easy maintenance

-

Energy savingSingle machine saves 15% to 30% energy,. Low noise and less dust.

Maximino

From Saudi Arabia

"VEST mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider VEST is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"VEST has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a VEST grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to VEST mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves VEST’s ‘Built for Decades’ promise."