SOLUTION

Cement Grinding Station

Processing Overview

Cement production involves two main steps. First is clinker production. Second is fine grinding of the cement clinker with gypsum and other auxiliary materials, such as slag and natural pozzolans, to produce finished cement.

The latter step is typically completed in a dedicated cement grinding plant.

A cement grinding plant, also referred to as a clinker grinding unit or finish grinding plant, is a standalone unit for producing finished cement.

Unlike integrated cement plants, which perform both clinker production and grinding, the core function of a cement grinding plant is to grind purchased clinker with additives, enabling flexible production closer to sales markets or resources.

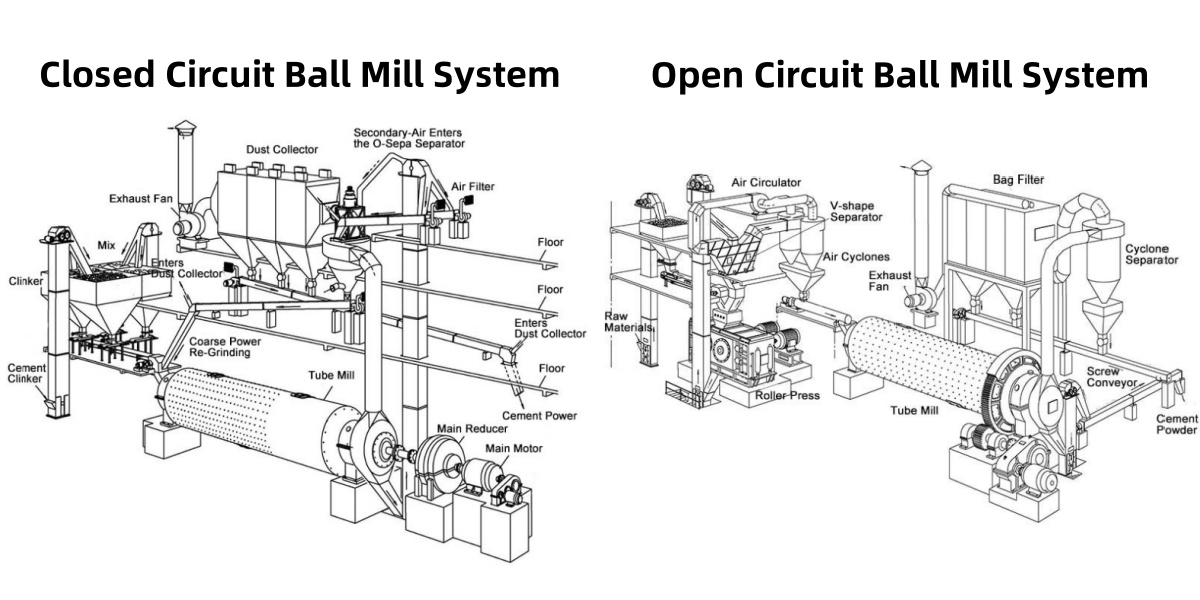

Process flow of Cement grinding mill production line

VEST has extensive experience in technology and offers a range of cement grinding plant solutions, including open-circuit and closed-circuit systems, featuring large ball mills and vertical mills.

In an open-circuit system, material passes through the grinding mill once, without classification and recovery of oversized lumps. To reach the required fineness, these systems often overgrind, producing particles finer than necessary and wasting energy.

In a closed-circuit system, coarse particles are separated from fine particles and returned for further grinding, eliminating the need for overgrinding and producing uniformly sized finished cement particles.

The core equipment in a cement grinding plant is the cement mill. Depending on the grinding system, commonly used cement mills include ball mills and vertical mills.

In addition to the cement mill, other common equipment in a cement grinding plant includes a cement mill concentrator, bag filters and electrostatic precipitators, cement silos, conveyors, bucket elevators, and cement rotary packaging machines.

Ball Mill vs Vertical Roller Mill

1.Cement Ball Mill – Rugged, Durable, and Reliable

Our cement ball mill, with its exceptional durability and extremely low failure rate, meets the demands of 24/7 continuous operation, minimizing downtime.

With a production capacity of up to 200 tons per hour, this model has been widely used by cement companies in the United States and the Middle East, consistently producing high-quality cement products with stable, efficient performance and low operating costs.

Core Values You’ll Receive:

• Heavy-duty steel construction resists pressure and deformation, suitable for demanding environments.

• Optimized liner structure significantly improves grinding efficiency and material handling capacity.

• High grinding ratio (up to 300), achieving a product fineness of up to 200 mesh.

• Suitable for both dry and wet processes, especially for grinding high-moisture raw materials.

• Widely suitable for the production of ordinary Portland cement and various blended cements.

2.Cement vertical mill – a four-in-one integrated system, highly efficient and energy-efficient.

More than just grinding – this equipment integrates grinding, drying, sorting, and conveying functions into one, achieving fully integrated operation.

With a grinding pressure 10 times higher than a ball mill, the vertical mill enables faster, finer, and more intelligent cement production, making it particularly suitable for large-scale, modern cement plants that require energy conservation and space conservation.

Core Values You’ll Receive:

• Reduced energy consumption by 30–50%, saving over $200,000 in annual electricity bills.

• Flexible adjustment of finished product fineness between 14 and 400 mesh to prevent overgrinding.

• Suitable for grinding both cement clinker and raw meal.

• Compact overall structure, requiring 40% less floor space than traditional systems.

• Especially suitable for high-volume, intensive, large-scale cement production lines.

What can VEST Machinery offer you?

Choosing a reliable partner is key to building an efficient cement grinding plant. VEST Machinery is your trusted partner, committed to providing comprehensive professional support and services.

Professional Customization : Provides personalized cement production line design solutions

Full-Service : Includes equipment installation, commissioning, operator training, and technical support until you are satisfied

Price Competitiveness : Factory direct pricing, high value for money

Fast Start-Up : Achieve operational success within 3-6 months

Flexible Production : Supports the production of ordinary Portland cement and various blended cements, meeting diverse cement production needs