SOLUTION

Calcium Carbonate Processing Plant

Processing Overview

A calcium carbonate plant, also known as a calcium carbonate processing plant or grinding plant, refers to a mechanized production line that produces calcium carbonate powder within a factory.

In today’s industrial sector, calcium carbonate powder is widely used as an important filler and coating material in industries such as PVC plastics, rubber, decorative coatings, slippers, and textiles. With the increasing global demand for high-quality calcium carbonate powder, more and more companies are seeking to build or expand calcium carbonate processing plants to improve production capacity and product competitiveness. This article will provide an in-depth introduction to the core equipment, production processes, and how to achieve efficient production through professional grinding equipment solutions in a calcium carbonate processing plant.

What is a calcium carbonate processing plant?

A calcium carbonate processing plant is a factory that uses mechanized production lines to produce calcium carbonate powder of varying fineness from raw materials such as limestone and marble through processes such as crushing, grinding, and grading.

The construction of a calcium carbonate production line needs to be customized according to specific requirements such as powder fineness and production capacity to ensure production efficiency and product quality.

Calcium Carbonate Production Process

1. Raw Material Preparation and Crushing:

Limestone, calcite, and other raw materials mined from quarries undergo fine screening and cleaning, followed by primary and secondary crushing using jaw crushers and hammer crushers to ensure the material particle size meets the requirements for subsequent grinding.

2. Grinding and Classification:

The crushed material enters a ball mill via a vibrating feeder, where it is ground into fine powder by the impact of the grinding balls. Subsequently, the material is blown into a classifier; the fine powder enters the product hopper, while the coarse powder is returned to the ball mill for regrinding, ensuring uniform particle size in the finished product.

3. Coating and Packaging:

If coating of calcium carbonate is required, a calcium carbonate surface treatment machine can be added to the production line, using materials such as stearic acid for coating. The final product is packaged using a fully automatic or semi-automatic packaging machine and stored for later use.

The entire production process can be fully automated, equipped with advanced dust removal and conveying systems to ensure environmental protection and high efficiency.

Core Equipment of a Calcium Carbonate Processing Plant

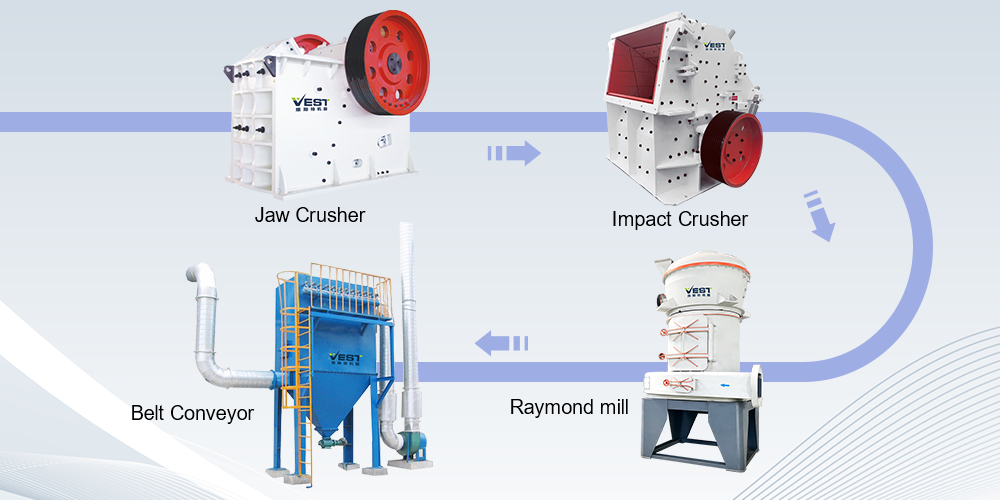

A calcium carbonate production plant includes a complete set of calcium carbonate production equipment. This includes, for example, crushers, vibrating feeders, bucket elevators or belt conveyors, calcium carbonate grinding mills, air classifiers, silos, dust collectors, packaging machines, etc.

Crushers

Mine-mined limestone particles are often too large to be directly fed into a calcium carbonate grinding mill. Furthermore, different calcium carbonate grinding mills have different requirements for feed particle size. Therefore, primary crushers and even secondary crushers are very important. Jaw crushers are typically used for crushing basic materials such as limestone or marble. Vibrating screens are also used to screen out qualified feed particles.

Grinding Mills

Calcium carbonate grinding mills are the core equipment of a calcium carbonate production plant. Currently, there are various types of calcium carbonate grinding mills on the market, such as ball mills, Raymond mills, vertical mills, etc.

Since different mills have different processing capacities and diameters, VEST can help you select the most suitable mill for your calcium carbonate grinding plant. Several factors need to be considered when selecting a grinding mill, such as raw material characteristics, required fineness, and production capacity.

Air Classifier

The calcium carbonate air classifier is used to further refine calcium carbonate powder. After being ground in a calcium carbonate mill, the calcium carbonate powder is fed into the air classifier.

Inside the mill, the airflow carries the lighter powder upwards for further grinding, while the coarser powder falls due to gravity. Using a calcium carbonate mill and air classifier together can produce fine and ultrafine calcium carbonate powder.

Dust Collector

To protect the environment and employee safety, calcium carbonate grinding plants are equipped with dust collectors. VEST offers a variety of dust collectors to ensure a dust-free working environment.

Powder Packaging Machine

Depending on the level of automation, VEST mainly offers two types of calcium carbonate powder packaging machines: semi-automatic and fully automatic. As the name suggests, the semi-automatic calcium carbonate packaging machine still requires manual completion of the packaging process.

The fully automatic calcium carbonate packaging machine can package and transport calcium carbonate powder to a designated area without human intervention. In addition, valve-type packaging machines and ton bag packaging machines are also available.

Advantages of VEST Calcium Carbonate Processing Plant

1.Customized Solutions :

We provide turnkey projects tailored to customer needs regarding powder fineness, production capacity, and application areas, covering equipment selection, process design, and installation and commissioning.

2.Controllable Particle Size and High-Quality Finished Products :

Through advanced grinding and grading technologies, we produce calcium carbonate powder ranging from fine to ultrafine. Our products feature uniform particle size, high whiteness, and stability, suitable for demanding industries such as papermaking, plastics, and coatings.

3.Dry and Wet Grinding Processes :

We offer dry grinding solutions combining ball mills and classifiers, as well as vertical grinding mills to meet diverse production requirements.

4.Automated Control :

Our PLC control system monitors the production line operation in real time, adjusting material parameters to improve production efficiency and stability.

5.Environmentally Friendly and Highly Efficient :

The entire system is equipped with a dust removal system, ensuring the production process meets environmental requirements while reducing labor costs and achieving high-efficiency production.

Applications of Calcium Carbonate Powder

Calcium carbonate powder, due to its high whiteness, light scattering, and chemical stability, is widely used as a filler and pigment:

Paper Industry: Improves paper opacity and brightness.

Plastics and Rubber: Enhances product mechanical properties and surface gloss.

Coatings and Building Materials: As an inexpensive filler, it improves coating coverage and durability.

Textiles and Slippers: Improves material feel and functionality.

How to Choose Calcium Carbonate Production Equipment?

The preparation methods of calcium carbonate powder include mechanical grinding (dry and wet processes) and chemical precipitation. Mechanical grinding obtains calcium carbonate powder through crushing, grinding, and classification, while chemical precipitation produces precipitated calcium carbonate through the reaction of quicklime and carbon dioxide. Choosing the appropriate grinding equipment and process based on production needs is crucial.

Why Choose Our Calcium Carbonate Production Line Equipment?

We specialize in the design and engineering of calcium carbonate processing production lines, providing complete equipment from crushing and grinding to packaging, ensuring efficient, environmentally friendly, and cost-effective production lines. Our core advantages include:

Extensive project experience and professional technical support.

Customizable equipment solutions to meet varying production capacity and fineness requirements.

Fully automated control reduces operating costs.

High-quality finished products help customers enhance their market competitiveness.

If you are planning a calcium carbonate processing plant or need to upgrade existing equipment, please contact us! Our professional team will provide you with a one-stop solution to help you achieve efficient production and business growth.