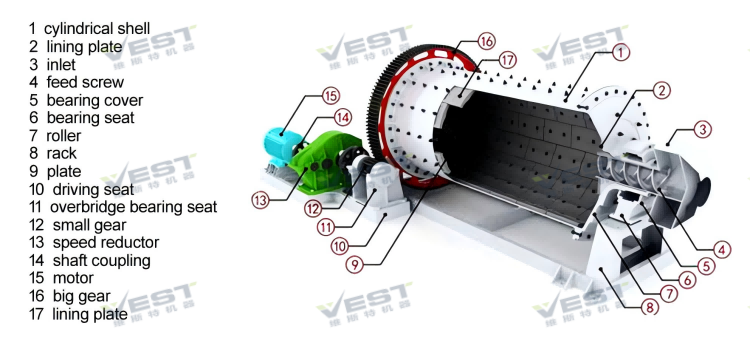

Ball Mill Working principle

Ball mill works by using balls to grind materials. Materials such as iron ore, pain and ceramics are added to the ball mill. Next, the ball mill is activated so that it rotates — either on its vertical or horizontal axis. As the ball bill rotates, the balls bounce around while striking the enclosed material. The force of these strikes helps to grind the material into a finer, less-coarse medium. Depending on the requirements, ball mills can be operated in different modes: Wet Grinding & Dry Grinding.

Product Characteristics

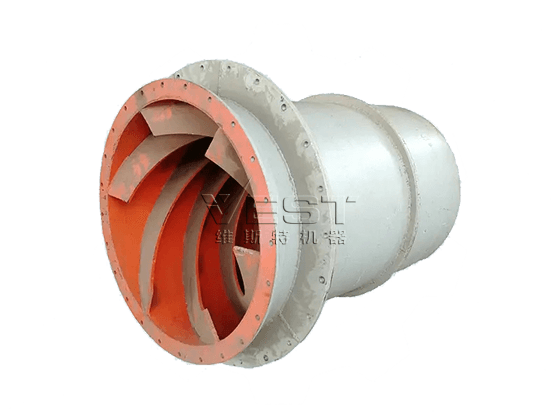

- Energy Consumption

- Low starting current and flexible starting;It uses rolling bearings instead of the original sliding bearings, it reduces friction, energy consumption and saves more than 30% of electricity;

- Increased Production

- Aimix energy saving ball mills are equipped with rolling bearing supports instead of tile sliding bearing supports, the energy saving is 10-20% and the production capacity is increased by 10-20% with the same power;

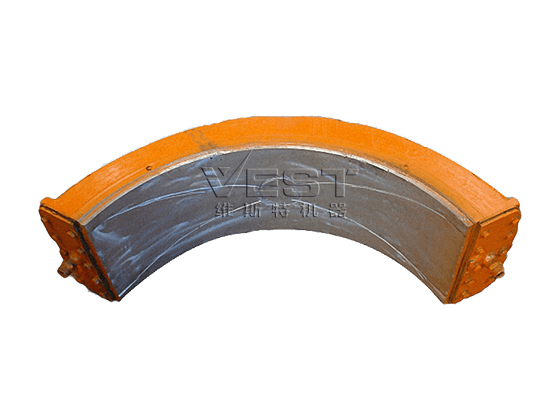

- Running smoothly

- The cylinder adopts automatic welding, ultrasonic detection, overall annealing and other measures to make the equipment run smoothly and with high efficiency.

Maximino

From Saudi Arabia

"VEST mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider VEST is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"VEST has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a VEST grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to VEST mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves VEST’s ‘Built for Decades’ promise."