CASE

2-3tph Limestone Grinding Plant In Saudi Arabia

Introduction

Project Background

Saudi Arabia, a globally significant oil and resource-rich nation, faces a growing demand for basic materials, such as limestone, for its construction and industrial development. Saudi Arabia boasts abundant limestone resources, which are widely used in construction, cement production, and glass manufacturing.

Equipment Selection and Technical Features

The MTM European Trapezoidal Mill selected for this project is a highly efficient grinding machine widely used in the market for processing hard materials such as limestone. Its key technical features include:

High Grinding Capacity: The MTM European Trapezoidal Mill utilizes a curved blade design, increasing the grinding surface and improving grinding efficiency. The cage classifier improves separation accuracy, eliminates “coarse powder loss,” and ensures uniform product particle size.

Stability and Reliability: Constructed of high-quality materials, the equipment boasts a compact structure and stable operation, making it suitable for continuous operation. A thin oil lubrication system extends bearing life and reduces maintenance costs.

Environmental Protection and Energy Saving: The equipment is equipped with a highly efficient dust removal system, reducing dust emissions and ensuring excellent noise control. The resistance-free volute design ensures excellent material flow and low energy consumption.

Adaptability: The MTM European Trapezoidal Mill is suitable for a wide range of materials, including limestone, quartz, and dolomite, and is particularly well-suited for processing medium-hard materials.

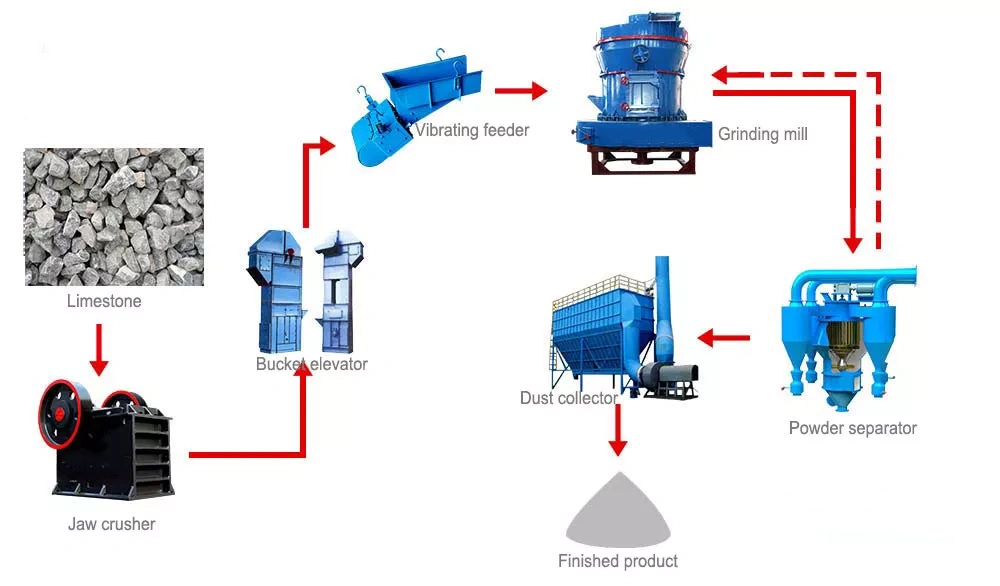

Limestone Mill Plant Process: Crushing, Grinding, Powder Selection, and Packaging

1. Crushing. Large lumps of material are crushed into a suitable particle size to meet the feed requirements of the Raymond mill. Common crushing equipment includes jaw crushers and hammer crushers.

2. Grinding. Crushed limestone fragments are transported to a silo via a bucket elevator and then fed evenly and quantitatively into the grinding chamber of the MTM European Trapezoidal Mill via a vibrating feeder. This process primarily produces limestone powder, which can be processed to meet specific fineness requirements.

3. Powder Selection. The crushed limestone powder is screened by a classifier to ensure that each particle meets specified standards. Unqualified powder is separated by a classifier and returned to the main mill for re-grinding. Qualified limestone powder is selected. Coarse particles are collected and returned to the main mill for further grinding.

4. Packaging. Qualified limestone powder is generally stored in a silo or packaged before being sold as a commercial product.

Project Results

Since the Limestone Grinding Plant was put into operation, the project has achieved the following results:

Improved production efficiency: The processing capacity of 2-3 tons per hour has been maintained, meeting customers’ demand for a stable supply of fine limestone powder.

Stable product quality: The product has a uniform particle size distribution and meets the standards for construction and industrial applications.

Reduced operating costs: The equipment operates stably, with low maintenance costs and energy consumption, resulting in significant economic benefits.

Environmental compliance: The equipment effectively controls dust and noise during operation, meeting Saudi Arabia’s environmental requirements.