CASE

10 TPH Calcite Grinding Production Line in Mexico

Introduction

Feed Particle Size: ≤30mm

Processing Capacity: 10 tons/hour

Finished Particle Size: 0.173-0.044mm

Process Flow – Customizable based on actual needs

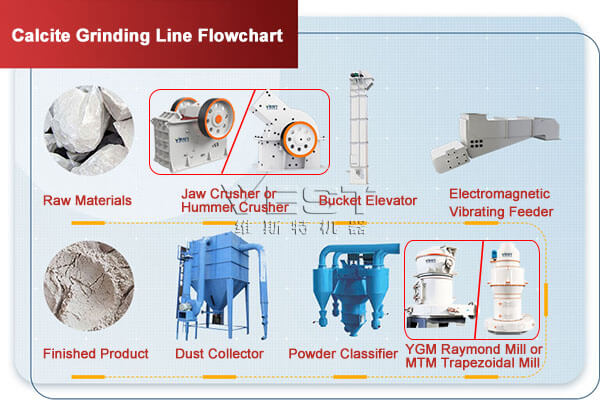

1. Calcite feed is fed into a crushing machine, such as a PE Jaw Crusher Machine or hammer crusher, for pulverization.

2. The pulverized material is conveyed via an elevator to a feeder and then to a YGM Raymond Mill or MTM Trapezoidal Grinding Mill for pulverization.

3. The processed powder is conveyed to a finished product silo for packaging.

Processing Advantages

1. This production line is rationally designed and equipped with advanced dust collectors, resulting in effective dust removal and dust-free operation.

2. Low investment cost, short payback period, and high future returns.

On-site experience speaks for itself

Calcite is a calcium carbonate mineral with a Mohs hardness of around 3 and is a common component of natural calcium carbonate. VEST Machinery designed a comprehensive production line tailored to the customer’s specific needs, ensuring smooth operation.

Customer Feedback

VEST’s Raymond mill is well-designed. Material is immediately classified by coarseness and fineness within the mill. Acceptable materials are discharged, while unacceptable materials are re-ground under internal wind power, ensuring the fineness of the finished product.